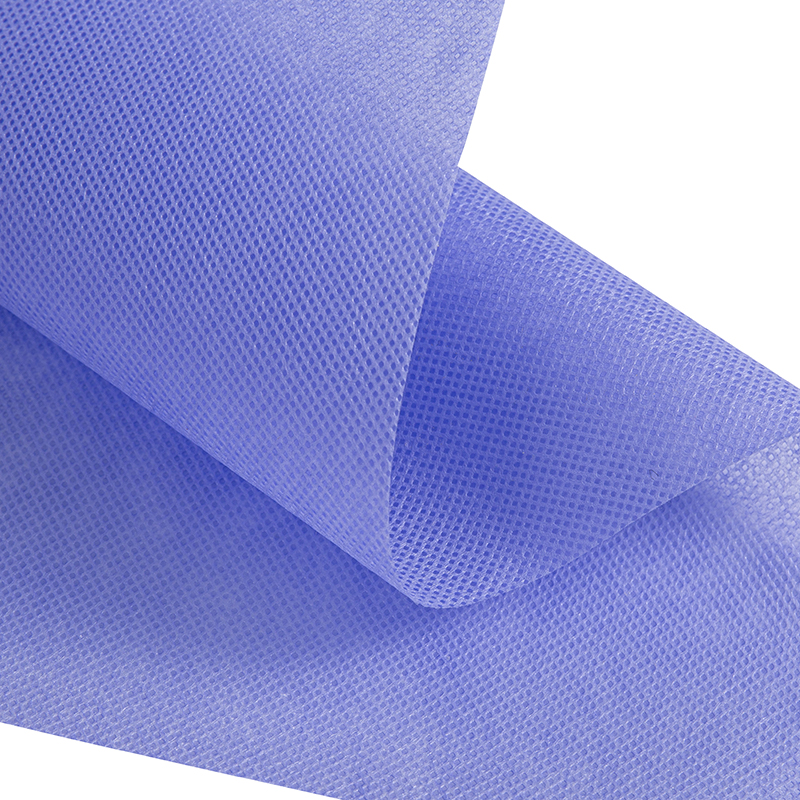

In the realm of advanced materials, meltblown non-woven fabrics have emerged as a cornerstone technology, particularly in critical applications like filtration and medical protection. This specialized fabric is produced through a unique meltblown process where polymer granules are melted, extruded through fine nozzles, and then attenuated by high-speed hot air to form microfibers. These microfibers are collected on a conveyor, creating a web with exceptionally fine fibers and random fiber orientation. The resulting material boasts a high surface area, complex porous structure, and excellent barrier properties, making it indispensable for capturing microscopic particles, droplets, and aerosols. Its significance has been profoundly highlighted in global health scenarios, where it serves as the critical filtering layer in respirators and the protective barrier in surgical gowns and drapes. Understanding the production, properties, and versatile applications of meltblown fabric is key to appreciating its vital role in safeguarding public health and enabling advanced industrial processes. This article delves deep into the science behind this material, its pivotal functions, and addresses common queries surrounding its use.

5 Key Long-Tail Keywords for Meltblown Non-Woven Fabrics

To effectively explore the topic of meltblown non-woven fabrics, it is crucial to target specific, searchable phrases that users are actively querying. These long-tail keywords combine search intent with lower competition, allowing content to reach a more targeted audience. The following five keywords are semantically related to the core topic and represent areas where detailed, professional information is highly sought after.

- how to improve filtration efficiency of meltblown fabric

- meltblown vs spunbond nonwoven for medical masks

- meltblown fabric production process step by step

- electret treatment for meltblown filter media

- specifications for medical grade meltblown nonwoven

Understanding the Meltblown Non-Woven Fabric Production Process

The manufacturing of meltblown non-woven fabrics is a sophisticated, integrated process that dictates the final material's performance. Unlike traditional weaving or knitting, the meltblown fabric production process step by step involves the direct conversion of polymer resin into a finished web of microfibers in a single, continuous operation. It begins with the feeding of polypropylene polymer granules into an extruder. The extruder melts the polymer under controlled heat and pressure, transforming it into a viscous liquid. This molten polymer is then forced through a die head containing hundreds of small nozzles. Simultaneously, high-velocity, heated air (often called process air) is blown onto the polymer streams as they exit the nozzles. This action attenuates and draws the polymer, creating extremely fine fibers with diameters typically in the micrometer range. These fibers are then blown onto a moving collector conveyor or forming drum, where they entangle and bond through self-adhesion and air turbulence, forming a coherent, non-woven web without the need for additional binders. The speed of the collector and the airflow dynamics control the fabric's basis weight and thickness. This entire process results in a material with a complex, three-dimensional network of pores ideal for filtration.

- Polymer Preparation: Raw polymer (typically polypropylene) is dried and fed into the system.

- Extrusion: The polymer is melted and homogenized in the extruder.

- Fiber Formation: Molten polymer is extruded through die nozzles and attenuated by hot air jets.

- Web Formation: Attenuated microfibers are randomly deposited onto a moving collector.

- Bonding: Fibers bond thermally upon contact with each other on the collector.

- Winding: The final fabric is wound into large rolls for further conversion.

Key Factors Influencing Meltblown Fabric Quality

The quality and performance characteristics of the final meltblown non-woven fabric are not accidental; they are precisely engineered through the control of several critical process parameters. Even minor adjustments in these variables can significantly alter the fabric's fiber diameter, pore size distribution, breathability, and strength. For instance, the temperature and pressure of the process air directly influence how thoroughly the polymer is attenuated, which in turn determines the fineness of the fibers. Finer fibers generally lead to a denser web with smaller pores, enhancing filtration efficiency but potentially increasing air resistance. Similarly, the die-to-collector distance (DCD) affects how the fibers cool and settle, impacting the fabric's loft and hand feel. Understanding and optimizing these factors is the first step in learning how to improve filtration efficiency of meltblown fabric without compromising other essential properties like breathability, which is crucial for user comfort in masks.

- Polymer Melt Flow Rate (MFR): A higher MFR polymer flows more easily, facilitating the formation of finer fibers.

- Hot Air Temperature and Velocity: Controls the attenuation and stretching of the polymer streams.

- Die Nozzle Design and Layout: Affects the uniformity and density of the fiber stream.

- Die-to-Collector Distance (DCD): Influences fiber cooling, bonding, and the web's structural integrity.

- Collector Speed: Determines the basis weight (grams per square meter) of the final fabric.

The Pivotal Role of Meltblown Fabric in Filtration Systems

Meltblown non-woven fabrics are the workhorse of modern filtration, thanks to their unique structure of fine, randomly arranged fibers that create a tortuous path for fluid or air to pass through. The primary mechanism of filtration in these fabrics is not merely sieving but a combination of interception, inertial impaction, and diffusion, which allows them to capture particles much smaller than the average pore size. To significantly boost performance, most meltblown filter media undergo an electret treatment for meltblown filter media. This process imparts a permanent electrostatic charge to the polypropylene fibers, enabling them to attract and capture oppositely charged particles, such as dust, pollen, and most importantly, virus-laden droplets and aerosols. This electrostatic mechanism is a key factor in how to improve filtration efficiency of meltblown fabric while maintaining relatively low breathing resistance, a critical balance for respiratory protection equipment. The application of meltblown fabric in filtration spans from the HVAC systems that clean the air in buildings to the fuel filters in vehicles and the vital face masks that protect individuals.

- Mechanical Filtration: Captures particles via direct sieving, interception, and inertial impaction.

- Electrostatic Filtration: Enhances particle capture through charged fibers (electret treatment).

- High Filtration Efficiency: Capable of filtering sub-micron particles with high efficacy.

- Low Pressure Drop: The open, fibrous structure allows for good airflow with minimal resistance.

- Customizable Properties: Filtration performance can be tailored by adjusting fiber size, basis weight, and charge level.

Meltblown vs. Spunbond: A Comparative Analysis for Filtration

When discussing non-wovens for protective applications, a common comparison arises: meltblown vs spunbond nonwoven for medical masks. While both are polypropylene-based non-wovens, their production processes and resulting properties are distinctly different, leading to complementary roles. Spunbond fabric is created by extruding and stretching filaments which are then laid down and bonded, resulting in a fabric with stronger, continuous fibers. This makes spunbond material strong, durable, and with relatively larger pores, making it ideal for the outer and inner layers of a mask for structural integrity and comfort. In contrast, meltblown fabric consists of much finer, discontinuous microfibers, creating a dense, web-like structure perfect for filtration. Therefore, in a typical 3-ply surgical mask, the spunbond layers act as protective shells, while the central meltblown layer is the critical filter.

| Feature | Meltblown Non-Woven | Spunbond Non-Woven |

| Fiber Characteristic | Fine, discontinuous microfibers (1-5 µm) | Coarser, continuous filaments (15-30 µm) |

| Primary Function | Filtration, Barrier | Strength, Cover, Durability |

| Typical Use in Masks | Middle Filter Layer | Inner and Outer Layers |

| Breathability | Moderate (can be restrictive if dense) | High |

| Strength | Lower, more brittle | Higher, tougher |

Meltblown Fabric in Medical Protection: Standards and Applications

In the medical field, the stakes for material performance are exceptionally high, governing the safety of both healthcare workers and patients. Meltblown non-woven fabrics are a fundamental component in this ecosystem, primarily serving as the barrier against fluid penetration and microbial transmission. To ensure reliability, medical devices incorporating this material must adhere to strict specifications for medical grade meltblown nonwoven. These specifications are defined by international standards (such as ASTM, EN, and ISO) and cover a range of performance criteria. Key among these are fluid resistance, which measures the material's ability to resist penetration by synthetic blood or other liquids; breathability, which impacts wearer comfort; filtration efficiency for both particulate and bacterial filtration; and material integrity. The application of meltblown fabric in medical protection is vast, forming the core of N95 respirators, surgical masks, surgical gowns, drapes, and sterilization wraps for surgical instruments.

- Surgical and Procedure Masks: The meltblown layer is the primary filter for aerosols and droplets.

- N95 and FFP2 Respirators: Often use multiple layers of charged meltblown fabric for high-efficiency particulate filtration.

- Surgical Gowns: Used in critical zones to provide a barrier against blood and other potentially infectious fluids.

- Sterilization Wraps: Allows steam to penetrate for sterilization while maintaining a sterile barrier.

- Surgical Drapes: Creates a sterile field around a surgical site.

Meeting Medical Grade Specifications

Adhering to the specifications for medical grade meltblown nonwoven is non-negotiable for manufacturers. These standards provide a quantifiable measure of a material's protective capabilities. For instance, a surgical mask material in Europe must comply with EN 14683, which classifies masks based on their Bacterial Filtration Efficiency (BFE) and breathability (differential pressure). A Type IIR mask, required for surgical procedures, must have a BFE of greater than 98% and also demonstrate splash resistance against blood. Similarly, the material used in the critical zone of a surgical gown must pass specific tests for hydrostatic pressure resistance to block fluid penetration. The production of such high-performance material involves not only precise control of the meltblown process but also stringent quality control checks for every batch, ensuring consistency and reliability in life-saving applications.

- Bacterial Filtration Efficiency (BFE): Measures the percentage of bacteria filtered out; typically >95% for medical masks.

- Particulate Filtration Efficiency (PFE): Measures filtration of sub-micron particles; crucial for respirators.

- Fluid Resistance: Tested by exposing the material to a column of synthetic blood.

- Breathability (Delta P): Measures air pressure difference across the fabric; lower is better for comfort.

- Flammability: Must meet specific standards to ensure safety in oxygen-rich environments.

FAQ

What is the difference between a surgical mask and an N95 respirator?

The fundamental difference lies in the design, fit, and filtration capability, all of which are enabled by the use of meltblown non-woven fabrics. A surgical mask is a loose-fitting, disposable device that creates a physical barrier between the wearer's mouth and nose and potential contaminants in the immediate environment. It typically has a 3-ply structure with one meltblown filter layer sandwiched between two spunbond layers. Its primary function is to protect the environment from the wearer's respiratory emissions. In contrast, an N95 respirator is a tight-fitting device designed to achieve a very close facial fit and efficient filtration of airborne particles. It often utilizes multiple layers of electrostatically charged meltblown fabric and is certified to filter at least 95% of airborne particles. The seal and the high-quality filter media make the N95 a personal protective equipment (PPE) to protect the wearer from inhaling hazardous aerosols.

Can meltblown masks be reused or sterilized?

This is a complex question with significant implications for the performance of the meltblown non-woven fabric. In general, disposable masks and respirators incorporating meltblown media are designed for single use. The primary concern with reuse and sterilization methods is the degradation of the material's filtration efficiency. The critical component is the electret treatment for meltblown filter media, which imparts an electrostatic charge. Methods involving heat, moisture, or chemicals (such as autoclaving, boiling, or using alcohol-based disinfectants) can neutralize this charge, drastically reducing the fabric's ability to capture fine particles via electrostatic attraction. While some methods like vaporized hydrogen peroxide or UV light have been studied and show less degradation, they are not practical for home use and can affect the material's structure over time. Therefore, for guaranteed protection, it is strongly recommended to use these products as intended—on a single-use basis.

How does the electret treatment work in meltblown fabric?

The electret treatment for meltblown filter media is a pivotal technological advancement that supercharges the filtration performance of meltblown non-woven fabrics. An electret is a dielectric material that has a quasi-permanent electric charge. In the meltblown process, this charge is imparted to the polypropylene fibers either during web formation (corona charging) or after production (e.g., triboelectric charging or corona charging again). This process aligns the dipoles within the polymer structure, creating a persistent electric field around the fibers. When airborne particles pass through this charged web, several mechanisms come into play. Neutral particles become polarized and are attracted to the charged fibers. Already charged particles are directly attracted via Coulombic forces. This electrostatic attraction allows the fabric to capture particles that are much smaller than the physical gaps between the fibers, resulting in high filtration efficiency at a relatively low breathing resistance. This is a key answer to how to improve filtration efficiency of meltblown fabric without making it unbreathable.

What are the key specifications to look for in medical-grade meltblown material?

When evaluating specifications for medical grade meltblown nonwoven, several key performance metrics are critical. These are typically verified by independent testing laboratories and should align with recognized international standards. Firstly, Filtration Efficiency is paramount. This is broken down into Bacterial Filtration Efficiency (BFE) for masks and Particulate Filtration Efficiency (PFE) for respirators, both expressed as a percentage. Secondly, Breathability, measured as differential pressure (Delta P), is crucial for wearer comfort; a lower value indicates easier airflow. Thirdly, for applications involving liquids, Fluid Resistance is tested by measuring the pressure at which penetration occurs. Additionally, Strength properties like tensile strength are important for durability during use. Understanding these specifications helps in selecting the appropriate material for the intended medical application, ensuring it provides the necessary level of protection.

English

English  русский

русский  Español

Español