The global demand for synthetic textiles has driven significant innovations in thermoplastic polymer extrusion. At the heart of this industrial shift is the PP non-woven fabric making machine. This equipment utilizes the spunbond process to convert polypropylene granules into high-strength, breathable fabrics used in m...

READ MORECustom PP Spunbond Non Woven Fabric Manufacturers

-

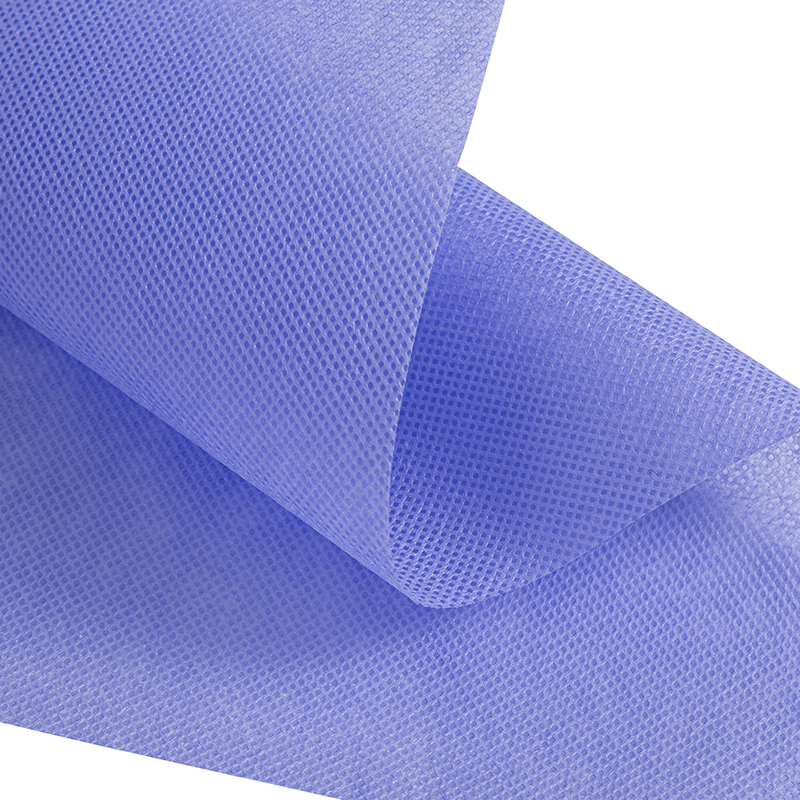

Checkered PP Spunbond Non Woven Fabric for Handbags

Checkered PP spunbond handbag nonwoven fabric is a checkered nonwoven fabric made of polypropylene (PP) using a spunbond process. Through high-tempera...

-

Cross Polypropylene Spunbond Sofa Lining Nonwoven Fabric

Cross-grain polypropylene spunbond sofa lining non-woven fabric is a functional fabric made of polypropylene through spinning, web laying and thermal ...

-

Checkered Spunbond PP Nonwoven Fabric for Medical Masks

The material for the checkered spunbonded PP non-woven mask is made of polypropylene (PP) as the main raw material through advanced spunbonding techno...

-

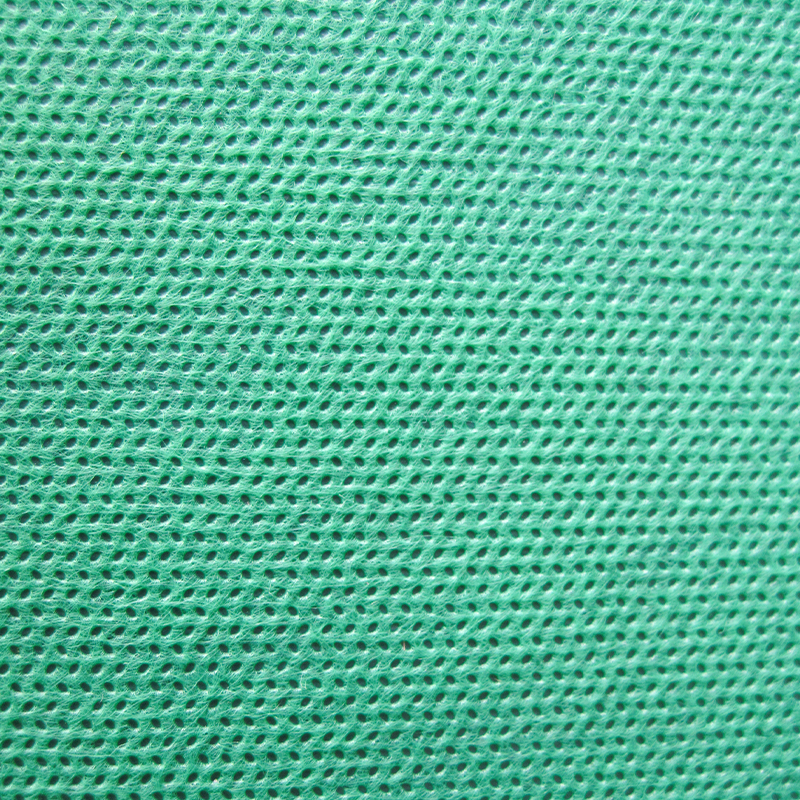

Spunbond PP Checkered Nonwoven Fabric for Agricultural Film

Spunbond PP checkered non-woven agricultural film is a functional agricultural covering material made of polypropylene (PP) through a spunbond process...

-

Checkered PP Spunbond Nonwoven Sofa Lining Fabric

Checkered PP spunbond sofa lining nonwoven fabric is a functional material made of polypropylene (PP) using a spunbond process. Through a special grid...

-

PP Printed Spunbond Non Woven Fabric for Gift Packing

PP printed spunbond nonwoven fabric is an environmentally friendly packaging material specially designed for gift packaging. It uses polypropylene (PP...

-

Printed Disposable PP Non-Woven Fabric Roll for Shopping Bag

Printed shopping bag disposable non-woven fabric roll is an environmentally friendly packaging material made of polypropylene (PP) as the main raw mat...

-

Colorful Sesame PP Spunbond Nonwoven Interlining Fabric

The colorful waterproof sesame pattern PP spunbond nonwoven interlining is a functional nonwoven material made of polypropylene (PP) through spinning,...

-

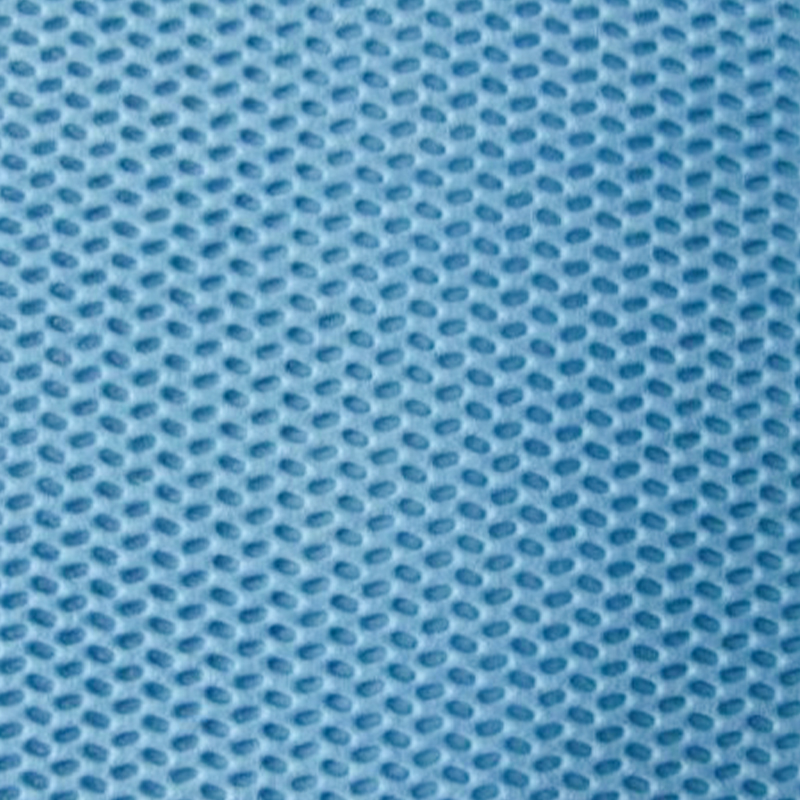

Sesame Spot Spunbond Polypropylene Non Woven Interlining Fabric

Sesame pattern spunbond polypropylene hydrophilic lining nonwoven fabric is a functional nonwoven material made by spunbonding process with polypropyl...

-

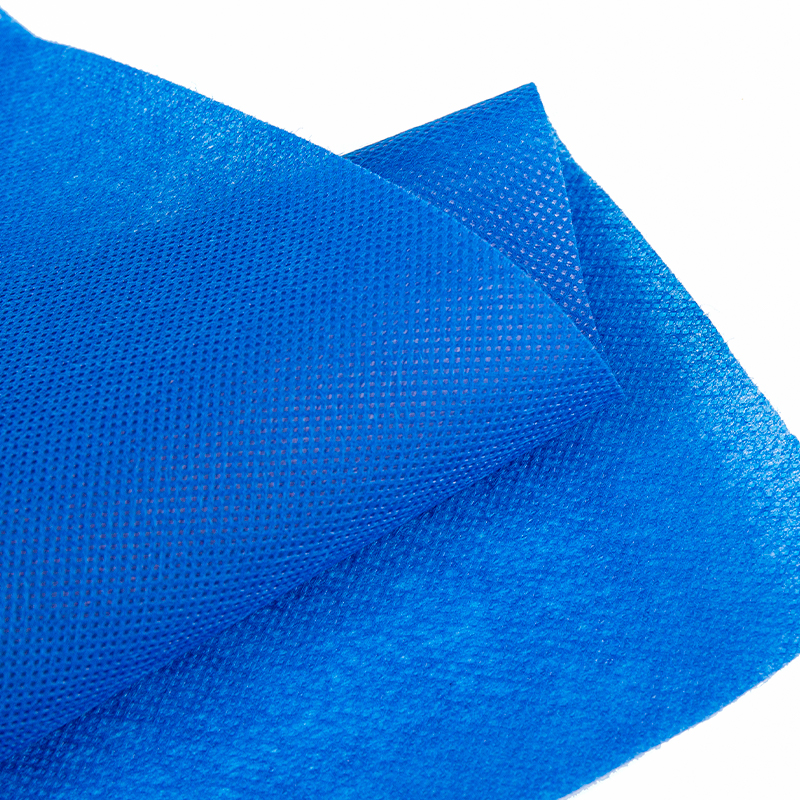

Cross Cambrella PP Spunbonded Non-woven Fabric for Eco-friendly Bags

The cross-grain Canberra polypropylene non-woven environmentally friendly bag roll is made of polypropylene (PP) as the base material through high-tem...

-

Checkered Colored PP Spunbond Non Woven Fabric for Luggage Bags

Checkered color PP spunbond nonwoven fabric for luggage bags is a functional nonwoven fabric made of polypropylene (PP) as the main raw material throu...

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. is

China Custom PP Spunbond Non Woven Fabric Manufacturers and

PP Spunbond Non Woven Fabric Suppliers.Jingang is a professional enterprise specializing in the research, development, and manufacturing of nonwoven materials and supporting equipment. Located in Jiangyin, Jiangsu Province, China, the company offers a wide range of products including PP spunbond and meltblown nonwovens, which are widely used in industries such as automotive, agriculture, packaging, and deep glass processing.In addition to nonwoven materials, we independently design and manufacture a variety of specialized machinery, including nonwoven production lines, CNC glass edging machines, and printing equipment—dedicated to providing customers with systematic and automated production solutions.

Over the past 26 years, we have remained committed to technological innovation and quality control. In 2002, we successfully developed German-style spunbond technology, improving the stability and efficiency of domestically produced equipment. In 2009, we launched CNC edging machines for shaped glass, expanding the application scope of glass processing. These milestones have played a key role in positioning our company at the forefront of the industry.

We have established a sound quality management system and strictly implement multi-stage inspection processes to ensure our products meet international standards. Through flexible customization, professional technical support, and reliable delivery capabilities, Jiangyin Jingang has built long-term partnerships with clients at home and abroad, earning a solid reputation in the market.We will continue to provide reliable products, strong technical expertise, and practical services to deliver more efficient and sustainable solutions to customers around the world.

-

-

In the evolving landscape of sustainable textiles, Checkered PP Non-Woven Fabric has emerged as a high-performance material that bridges the gap between aesthetic appeal and structural integrity. Engineered primarily through the spunbond process, this fabric utilizes 100% virgin polypropylene (PP) resins to create a we...

READ MORE -

Sesame Pattern PP Non-Woven Fabric, characterized by its distinctive textured surface resembling sesame seeds, is a specialized variant of polypropylene non-woven material. Its unique manufacturing process creates a pattern that significantly enhances its functional properties, making it a standout choice for demanding...

READ MORE

Applications of PP Spunbond Non Woven Fabric in Medical, Agriculture, and Packaging Industries

PP Spunbond Non Woven Fabric, made from 100% polypropylene polymer, is one of the most versatile and widely used nonwoven materials today. It is produced through an integrated process in which thermoplastic polypropylene is melted, extruded into continuous filaments, and then bonded thermally to form a uniform, strong, and breathable fabric. This material combines high tensile strength, lightweight characteristics, excellent chemical resistance, and cost-effectiveness—making it an essential material in many industrial and consumer applications.

Material Properties and Performance Parameters

The performance of PP spunbond nonwoven fabric can be customized by adjusting fiber fineness, fabric weight, and bonding density. Below is a general reference of typical material parameters:

- Raw Material: Polypropylene (PP)

- Fabric Weight Range: 10 – 250 g/m²

- Width Range: Up to 3200 mm

- Tensile Strength: ≥ 120 N/5cm (varies by weight)

- Elongation: 15% – 40%

- Air Permeability: 100 – 900 L/m²/s

- UV Resistance: Customizable (1%–3% UV stabilizer optional)

- Melting Point: 165°C

- Color Options: White, Blue, Green, Black, Customized

- Recyclability: 100% recyclable and eco-friendly

Applications in the Medical Industry

In the healthcare sector, PP spunbond nonwoven fabric is an indispensable material used in the production of disposable protective and hygiene products. Its structure provides effective barrier properties against liquids and microorganisms while maintaining breathability and comfort. Common applications include surgical gowns, face masks, disposable bed sheets, patient drapes, and sterile packaging.

The material can be treated with antistatic, antibacterial, or hydrophobic coatings to enhance performance under specific medical conditions. Its soft touch and non-irritating surface make it suitable for direct skin contact, ensuring both safety and comfort during medical procedures.

Applications in the Agriculture Industry

PP spunbond nonwoven fabric plays a significant role in modern agricultural management. Farmers use it as a protective cover for plants and crops to control temperature, humidity, and light exposure. The fabric prevents weed growth, conserves soil moisture, and shields plants from insects and heavy rainfall. Its UV-stabilized variants can withstand long-term outdoor exposure, ensuring reliable protection for multiple growing seasons.

Additionally, it is used in seedling nurseries, greenhouse shading, and soil separation applications. Compared with traditional plastic films, nonwoven crop covers offer better air permeability and reusability, contributing to environmentally sustainable farming practices.

Applications in the Packaging Industry

In packaging, PP spunbond nonwoven fabric is increasingly replacing single-use plastics due to its strength, printability, and recyclability. It is used to manufacture reusable shopping bags, gift packaging, storage covers, and industrial protective wraps. The fabric can be laminated with other materials (such as meltblown or film layers) to improve waterproofness and durability while retaining flexibility.

For industrial packaging, PP nonwovens offer excellent tear resistance and protect products from dust, moisture, and impact during transportation. Its customizable thickness and color range also make it suitable for premium and branded packaging solutions.

Technological Innovation and Quality Assurance

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. has more than two decades of expertise in developing and manufacturing advanced nonwoven materials and supporting equipment. The company’s product portfolio covers PP spunbond, meltblown, and composite nonwovens, widely used in automotive, agriculture, packaging, and filtration sectors. Through continuous innovation, the company introduced German-style spunbond technology in 2002, improving product stability and efficiency across domestic production lines.

In addition to nonwoven materials, the company independently designs and manufactures specialized machinery such as nonwoven production lines, CNC glass edging machines, and printing equipment—providing comprehensive automation solutions for global clients. Strict quality control measures, from raw material inspection to multi-stage product testing, ensure every batch meets international performance standards.

Commitment to Sustainable Development

With growing environmental awareness, Jiangyin Jingang Nonwoven Co., Ltd. focuses on producing eco-friendly and recyclable nonwoven fabrics. The company promotes low-emission production processes and energy-efficient equipment to minimize carbon footprints. Its PP spunbond fabrics are 100% recyclable and can be reused or repurposed into secondary industrial materials, supporting a circular economy model.

Through technological advancement, consistent quality, and global service capabilities, Jiangyin Jingang continues to deliver reliable, efficient, and sustainable nonwoven fabric solutions for medical, agricultural, and packaging industries—empowering customers to build safer, cleaner, and greener production systems worldwide.

How to Choose High-Quality PP Spunbond Non Woven Fabric for Industrial Use

PP Spunbond Non Woven Fabric is one of the most widely used materials in modern industry, known for its durability, flexibility, and cost-effectiveness. Selecting the right PP spunbond nonwoven fabric is crucial for ensuring optimal performance in various industrial applications such as filtration, agriculture, packaging, and construction. Understanding the key factors that determine quality can help businesses make informed purchasing decisions and achieve better long-term value.

1. Evaluate Raw Material Purity and Fiber Consistency

The foundation of high-quality PP spunbond fabric lies in the purity of its raw material—polypropylene. 100% virgin polypropylene ensures superior strength, elasticity, and resistance to aging compared to recycled or blended polymers. A uniform fiber diameter and consistent filament distribution contribute to even surface texture and improved mechanical performance. Inconsistent fiber quality may lead to weak spots, uneven thickness, or reduced tensile strength in end applications.

2. Consider Fabric Weight and Structural Uniformity

Fabric weight (measured in grams per square meter, or GSM) directly affects the material’s strength, flexibility, and suitability for different uses. Lighter fabrics (10–40 GSM) are ideal for disposable hygiene and medical applications, while medium and heavy fabrics (60–250 GSM) are preferred for industrial and agricultural use. When choosing a supplier, ensure the fabric weight is consistent across its width and length, as uneven bonding or fiber density can compromise product reliability and performance.

3. Check Tensile Strength and Durability

Industrial-grade PP spunbond nonwoven fabrics must withstand stress, stretching, and environmental exposure. High tensile strength ensures that the fabric maintains integrity during cutting, processing, and long-term use. Additionally, durability is enhanced through proper thermal bonding, which reinforces the structure without compromising flexibility. Reliable manufacturers test each production batch under standardized conditions to confirm that it meets specific tensile and elongation requirements for its intended purpose.

4. Examine Surface Finish and Functional Treatments

Depending on the application, surface finish plays a vital role in determining how the fabric interacts with other materials. For example, smooth and hydrophilic finishes are preferred in medical and filtration uses, while rougher or laminated textures are better for packaging and automotive interiors. Advanced treatments such as UV stabilization, anti-static coating, and hydrophobic finishing can significantly extend product lifespan and functionality. Selecting a fabric with the right finish ensures optimal performance in the target environment.

5. Evaluate Production Technology and Process Stability

Modern production technology is key to achieving consistency and precision in PP spunbond nonwoven fabrics. Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. has more than two decades of expertise in nonwoven production, integrating advanced German-style spunbond technology developed in 2002 to enhance efficiency and uniformity. Stable thermal bonding systems and automated filament control minimize variation, ensuring each roll of fabric meets strict quality standards. Process stability directly impacts product reliability, especially for large-scale industrial use.

6. Inspect Quality Management and Certification

High-quality PP spunbond fabric must meet both domestic and international standards for strength, safety, and environmental compliance. Reliable manufacturers implement a multi-stage inspection process—from raw material testing to final product evaluation—to guarantee consistency and traceability. Jiangyin Jingang Nonwoven Co., Ltd. follows a comprehensive quality management system and conducts continuous product testing to maintain superior standards across its production lines. Certifications such as ISO9001 demonstrate a manufacturer’s commitment to quality assurance and continuous improvement.

English

English  русский

русский  Español

Español