The global demand for synthetic textiles has driven significant innovations in thermoplastic polymer extrusion. At the heart of this industrial shift is the PP non-woven fabric making machine. This equipment utilizes the spunbond process to convert polypropylene granules into high-strength, breathable fabrics used in m...

READ MORECustom Cross Pattern PP Non-Woven Fabric Manufacturers

-

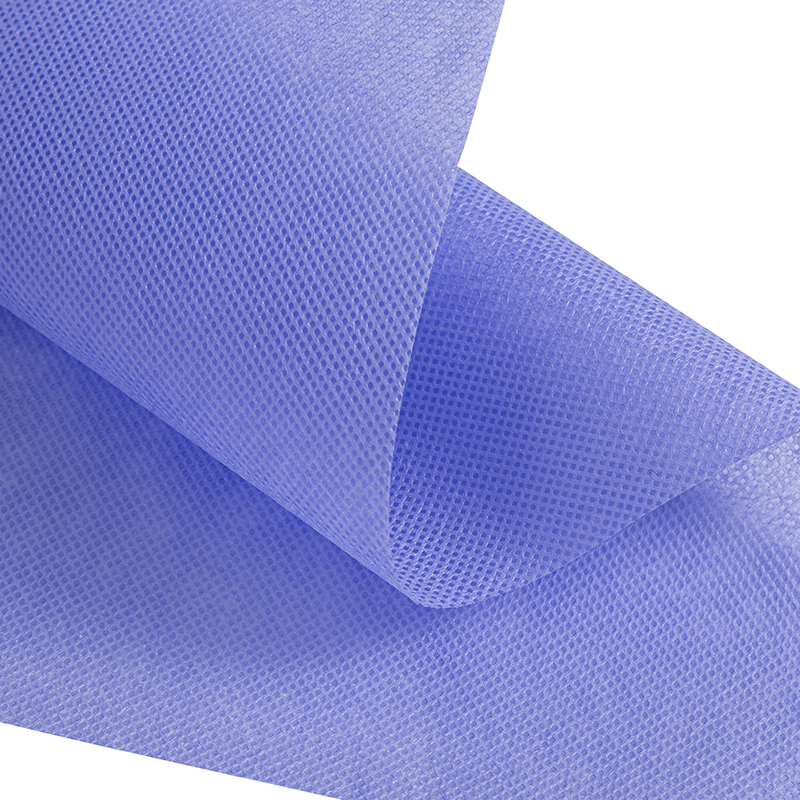

Cross Polypropylene Spunbond Sofa Lining Nonwoven Fabric

Cross-grain polypropylene spunbond sofa lining non-woven fabric is a functional fabric made of polypropylene through spinning, web laying and thermal ...

-

Cross Cambrella PP Spunbonded Non-woven Fabric for Eco-friendly Bags

The cross-grain Canberra polypropylene non-woven environmentally friendly bag roll is made of polypropylene (PP) as the base material through high-tem...

Spunbond PP cross-grain non-woven fabric is a non-woven fabric made of polypropylene (PP) fiber through a spunbond process. Its surface has a unique cross-grain design, which makes it both beautiful and practical in appearance and functionality. This product uses polypropylene as the main raw material. Through high-temperature melting, spinning, laying, hot rolling and other processes, the fine fibers are randomly arranged and bonded into cloth to form a high-strength and high-breathable material. Its cross-grain design not only improves the texture of the product, but also enhances its durability and comfort during use. Spunbond PP cross-grain non-woven fabric has the following characteristics: High strength and durability: Due to the use of spunbond technology, the fibers of this product are tightly bonded, with excellent tensile strength and tear resistance, and are suitable for scenes requiring high strength. Breathability and waterproofness: While maintaining good breathability, this material has natural waterproof properties, making it widely used in many fields such as medical care, agriculture, and packaging. Environmental protection and recyclability: Polypropylene material is non-toxic and harmless, and can be recycled and reused, which is in line with modern environmental protection concepts. Lightweight and soft: The product is Lightweight, easy to process and transport, and has a soft surface and comfortable touch, making it suitable for home and sanitary products. Versatility: Spunbond PP cross-grain non-woven fabric can be customized in color, weight and width according to customer needs, and is suitable for a variety of uses such as medical, agricultural, industrial, and packaging.

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. is

China Custom Cross Pattern PP Non-Woven Fabric Manufacturers and

.Jingang is a professional enterprise specializing in the research, development, and manufacturing of nonwoven materials and supporting equipment. Located in Jiangyin, Jiangsu Province, China, the company offers a wide range of products including PP spunbond and meltblown nonwovens, which are widely used in industries such as automotive, agriculture, packaging, and deep glass processing.In addition to nonwoven materials, we independently design and manufacture a variety of specialized machinery, including nonwoven production lines, CNC glass edging machines, and printing equipment—dedicated to providing customers with systematic and automated production solutions.

Over the past 26 years, we have remained committed to technological innovation and quality control. In 2002, we successfully developed German-style spunbond technology, improving the stability and efficiency of domestically produced equipment. In 2009, we launched CNC edging machines for shaped glass, expanding the application scope of glass processing. These milestones have played a key role in positioning our company at the forefront of the industry.

We have established a sound quality management system and strictly implement multi-stage inspection processes to ensure our products meet international standards. Through flexible customization, professional technical support, and reliable delivery capabilities, Jiangyin Jingang has built long-term partnerships with clients at home and abroad, earning a solid reputation in the market.We will continue to provide reliable products, strong technical expertise, and practical services to deliver more efficient and sustainable solutions to customers around the world.

-

-

In the evolving landscape of sustainable textiles, Checkered PP Non-Woven Fabric has emerged as a high-performance material that bridges the gap between aesthetic appeal and structural integrity. Engineered primarily through the spunbond process, this fabric utilizes 100% virgin polypropylene (PP) resins to create a we...

READ MORE -

Sesame Pattern PP Non-Woven Fabric, characterized by its distinctive textured surface resembling sesame seeds, is a specialized variant of polypropylene non-woven material. Its unique manufacturing process creates a pattern that significantly enhances its functional properties, making it a standout choice for demanding...

READ MORE

How Cross Pattern Design Enhances the Strength and Durability of PP Non-Woven Fabrics

Cross pattern PP non-woven fabric represents a significant innovation in nonwoven material engineering. Unlike conventional nonwoven fabrics where fibers are randomly oriented, the cross pattern arrangement interlaces fibers in multiple directions, creating a reinforced network. This structure evenly distributes stress and reduces weak points, significantly enhancing tensile strength and tear resistance. As a result, these fabrics are better suited for heavy-duty industrial and commercial applications.

The multidirectional fiber arrangement also improves dimensional stability. Traditional nonwoven fabrics can stretch or deform under tension, but cross pattern fabrics maintain their shape even under repeated mechanical stress. This makes them ideal for applications such as automotive interior components, protective packaging, agricultural covers, and filtration layers where consistent performance under stress is critical.

Durability is another key advantage. The cross pattern design enhances resistance to abrasion and wear. Fibers support each other in a lattice structure, minimizing fiber shedding and extending the product’s lifespan. In environments with high friction, frequent handling, or exposure to outdoor elements, cross pattern PP non-woven fabrics demonstrate superior longevity compared to standard designs.

Additional functional benefits include:

- Improved Load-Bearing Capacity: The cross pattern distributes weight across the fabric, preventing localized stress points.

- Enhanced Liquid Resistance: While PP fibers are inherently hydrophobic, the reinforced pattern helps maintain structural integrity when in contact with moisture.

- Better Thermal and Chemical Stability: The fabric retains performance under varying temperatures and is resistant to many chemicals used in industrial processes.

Jiangyin Jingang Nonwoven Co., Ltd. applies decades of expertise in nonwoven production and machinery development to manufacture cross pattern PP fabrics with precise control over fiber alignment, bonding, and density. Their fabrics undergo rigorous multi-stage inspections to ensure consistent mechanical performance, dimensional stability, and quality. Through flexible customization, clients can specify parameters tailored to their industry needs.

Typical technical specifications for cross pattern PP non-woven fabrics include:

| Parameter | Typical Value | Unit | Notes |

|---|---|---|---|

| Basis Weight | 20–150 | g/m² | Customizable based on application |

| Tensile Strength (MD/CD) | 30–120 / 25–100 | N/50mm | Depends on fiber orientation and bonding |

| Elongation at Break | 15–50 | % | Indicates flexibility under stress |

| Thickness | 0.2–1.2 | mm | Varies with weight and application |

| Air Permeability | 50–600 | L/m²/s | Important for filtration and breathable products |

In summary, the cross pattern design significantly enhances PP non-woven fabrics’ strength, durability, and stability. Combined with the technical expertise of Jiangyin Jingang Nonwoven Co., Ltd., these fabrics provide reliable, long-lasting performance for industries ranging from automotive and agriculture to packaging and glass processing. This makes them a preferred choice for applications requiring high mechanical strength, abrasion resistance, and dimensional consistency.

Key Advantages of Cross Pattern PP Non-Woven Fabric in Industrial and Medical Use

Cross pattern PP non-woven fabric has emerged as a versatile material that meets the rigorous demands of both industrial and medical applications. The unique cross pattern structure interlaces polypropylene fibers in multiple directions, which significantly enhances tensile strength, tear resistance, and dimensional stability. These properties make the fabric exceptionally durable, even under high mechanical stress, heavy loads, or repeated use.

In industrial applications, the cross pattern design provides several key advantages. The reinforced structure improves load-bearing capacity, allowing the fabric to serve as protective covers, packaging materials, filtration layers, and agricultural sheets that withstand prolonged wear and environmental exposure. Its resistance to abrasion and deformation ensures reliable performance in manufacturing processes, automotive interiors, and deep glass processing, where consistent strength and stability are critical.

For medical applications, cross pattern PP non-woven fabrics offer enhanced hygiene and safety features. The tightly interlaced fibers create a barrier against particles and fluids, making them suitable for surgical drapes, protective gowns, face masks, and disposable medical sheets. The structural integrity ensures that the fabric retains its protective properties even during extended use, while its lightweight and breathable nature provide comfort for medical personnel and patients.

Additional advantages of cross pattern PP non-woven fabrics include:

- Improved Dimensional Stability: Reduces stretching and deformation under tension, maintaining shape in critical applications.

- Enhanced Durability: Resistance to tearing, abrasion, and repeated handling extends service life.

- Customizability: Can be manufactured in various weights, thicknesses, and densities to meet specific industrial or medical requirements.

- Chemical and Thermal Resistance: Maintains performance in challenging environments and when exposed to cleaning agents or moderate heat.

Jiangyin Jingang Nonwoven Co., Ltd. has leveraged over two decades of expertise in nonwoven technology to produce high-quality cross pattern PP fabrics. Through precise fiber orientation, advanced bonding techniques, and rigorous multi-stage quality control, the company ensures that its products meet international standards and the exacting demands of both industrial and medical clients. Flexible customization and reliable production capabilities allow Jiangyin Jingang to provide solutions tailored to the specific needs of customers worldwide.

In summary, cross pattern PP non-woven fabrics offer a combination of strength, durability, and protective functionality, making them an ideal choice for industrial and medical applications. With the technical expertise and manufacturing excellence of Jiangyin Jingang, these fabrics deliver reliable performance, safety, and longevity across a wide range of demanding environments.

English

English  русский

русский  Español

Español