The global demand for synthetic textiles has driven significant innovations in thermoplastic polymer extrusion. At the heart of this industrial shift is the PP non-woven fabric making machine. This equipment utilizes the spunbond process to convert polypropylene granules into high-strength, breathable fabrics used in m...

READ MORECustom Printed PP Non Woven Fabric Manufacturers

-

PP Printed Spunbond Non Woven Fabric for Gift Packing

PP printed spunbond nonwoven fabric is an environmentally friendly packaging material specially designed for gift packaging. It uses polypropylene (PP...

-

Printed Disposable PP Non-Woven Fabric Roll for Shopping Bag

Printed shopping bag disposable non-woven fabric roll is an environmentally friendly packaging material made of polypropylene (PP) as the main raw mat...

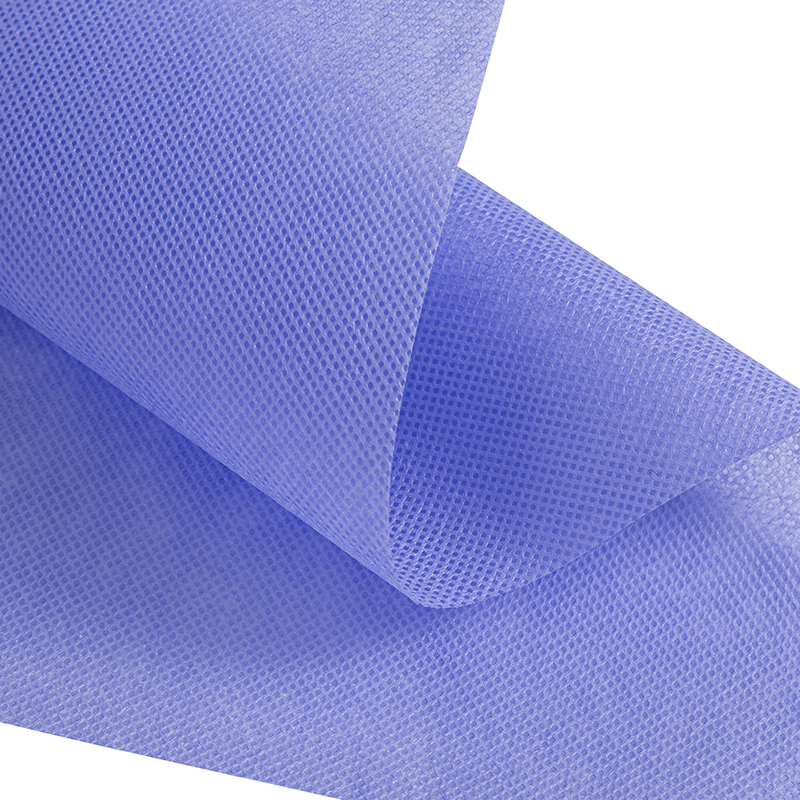

Spunbond PP printed non-woven fabric is a new type of environmentally friendly material made of polypropylene (PP) as the main raw material through the spunbond process. Its characteristics include water repellency, breathability, flexibility, non-combustibility, non-toxic and non-irritating, rich colors, etc. The material is produced by a continuous one-step process such as high-temperature melting, spinning, laying, hot pressing and winding, and has the advantages of good bidirectional fastness, diamond-shaped rolling points, wear resistance, and a firm feel. In addition, PP spunbond non-woven fabric also has the characteristics of high tenacity, small longitudinal and transverse differences, acid and alkali resistance, no radiation, harmless to the human body, good breathability, non-fading, eco-friendly and easy to degrade. In terms of application, spunbond PP printed non-woven fabrics are widely used in home textiles, packaging fabrics, outdoor products, medical and sanitary products, children's products, medical and sanitary products and other fields. Its products can be customized with various patterns and logos to meet the needs of different industries. For example, it can be used to make environmentally friendly shopping bags, non-woven bags, flower packaging cloth, luggage cloth, home decoration cloth (such as curtains, furniture covers, tablecloths, sofa cloth, window covers, wall cloth), needle-punched chemical fiber carpets, coating materials, etc. In addition, it is also suitable for filter materials, insulation materials, papermaking blankets, car shells, carpets, car seats, door linings, etc. in the industrial field. In the agricultural field, PP spunbond non-woven fabrics can be used as greenhouse ceiling materials (agricultural hotbeds).

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. is

China Custom Printed PP Non Woven Fabric Manufacturers and

.Jingang is a professional enterprise specializing in the research, development, and manufacturing of nonwoven materials and supporting equipment. Located in Jiangyin, Jiangsu Province, China, the company offers a wide range of products including PP spunbond and meltblown nonwovens, which are widely used in industries such as automotive, agriculture, packaging, and deep glass processing.In addition to nonwoven materials, we independently design and manufacture a variety of specialized machinery, including nonwoven production lines, CNC glass edging machines, and printing equipment—dedicated to providing customers with systematic and automated production solutions.

Over the past 26 years, we have remained committed to technological innovation and quality control. In 2002, we successfully developed German-style spunbond technology, improving the stability and efficiency of domestically produced equipment. In 2009, we launched CNC edging machines for shaped glass, expanding the application scope of glass processing. These milestones have played a key role in positioning our company at the forefront of the industry.

We have established a sound quality management system and strictly implement multi-stage inspection processes to ensure our products meet international standards. Through flexible customization, professional technical support, and reliable delivery capabilities, Jiangyin Jingang has built long-term partnerships with clients at home and abroad, earning a solid reputation in the market.We will continue to provide reliable products, strong technical expertise, and practical services to deliver more efficient and sustainable solutions to customers around the world.

-

-

In the evolving landscape of sustainable textiles, Checkered PP Non-Woven Fabric has emerged as a high-performance material that bridges the gap between aesthetic appeal and structural integrity. Engineered primarily through the spunbond process, this fabric utilizes 100% virgin polypropylene (PP) resins to create a we...

READ MORE -

Sesame Pattern PP Non-Woven Fabric, characterized by its distinctive textured surface resembling sesame seeds, is a specialized variant of polypropylene non-woven material. Its unique manufacturing process creates a pattern that significantly enhances its functional properties, making it a standout choice for demanding...

READ MORE

How to Choose the Right Printed PP Non Woven Fabric for Industrial and Consumer Products

Choosing the right Printed PP Non Woven Fabric for industrial and consumer products involves evaluating multiple aspects to ensure durability, functionality, and visual appeal. These fabrics are widely applied in packaging, agriculture, automotive, disposable products, and consumer goods, thanks to their lightweight structure, strength, and versatility.

Key Factors to Consider

Material Properties

- Base Weight (GSM): Typically ranges from 20–150 g/m² depending on application. Heavier fabrics offer greater strength for industrial use, while lighter fabrics are suited for consumer items like shopping bags.

- Tensile Strength: High tensile strength ensures durability, especially for applications such as reusable bags or agricultural covers.

- Thickness: Generally 0.05–0.3 mm; thicker fabrics provide more stability for industrial processes.

- Chemical and Moisture Resistance: Important for agricultural or packaging applications where exposure to water or chemicals may occur.

Printing Quality

- Printing Methods: Flexographic printing, gravure printing, and digital printing are commonly used. The method impacts color vibrancy, pattern clarity, and durability of the print.

- Ink Adhesion and Durability: Fabrics intended for repeated use or outdoor exposure require inks that resist fading and rubbing.

- Pattern Customization: Advanced printing equipment allows custom logos, graphics, or patterns tailored to branding needs.

Application Requirements

- Industrial Use: Demands high strength, tear resistance, and sometimes UV or heat resistance. Examples include packaging for heavy goods, automotive interiors, and protective covers.

- Consumer Use: Prioritizes appearance, softness, and eco-friendliness. Examples include shopping bags, promotional materials, and home textiles.

Supplier Expertise and Support

- Working with experienced manufacturers such as Jiangyin Jingang Nonwoven Co., Ltd. provides access to high-quality PP spunbond and meltblown nonwovens produced with advanced German-style technology.

- The company also offers specialized machinery and automated production lines, ensuring consistent product quality, customizable solutions, and timely delivery.

- A reliable supplier with multi-stage inspection and strong technical support helps guarantee compliance with international standards.

Typical Performance Parameters of Printed PP Non Woven Fabric

- GSM (Weight): 20–150 g/m²

- Thickness: 0.05–0.3 mm

- Tensile Strength: 15–50 N/cm (depending on weight and fiber type)

- Elongation at Break: 20–60%

- Air Permeability: 100–500 L/m²/s (affects breathability for agricultural or protective covers)

- Printing Compatibility: Flexographic, Gravure, Digital

- Chemical Resistance: Moderate to high (depending on polymer treatment)

- UV Resistance: Optional, based on additives for outdoor use

By carefully analyzing these parameters and considering the specific requirements of your intended application, businesses can select the most suitable Printed PP Non Woven Fabric. Combining functional performance with high-quality printing ensures both practical utility and visual appeal, whether for industrial applications or consumer products.

Sustainability and Eco-Friendly Practices in Printed PP Non Woven Fabric Production

Sustainability and eco-friendly practices have become increasingly important in the production of Printed PP Non Woven Fabrics, as industries and consumers alike seek materials that minimize environmental impact while maintaining high performance. Manufacturers are focusing on reducing waste, conserving energy, and employing recyclable or reusable materials throughout the production process.

Use of Eco-Friendly Materials

One key aspect of sustainability in PP nonwoven production is the use of high-quality raw materials that are safe, non-toxic, and can be recycled after use. Advanced production techniques, such as optimized spunbond and meltblown processes, help reduce material waste, improve energy efficiency, and lower carbon emissions. The choice of printing methods also plays a role: eco-friendly inks and water-based printing systems minimize harmful chemical usage and reduce environmental contamination.

Technological Innovation and Efficient Production

Companies like Jiangyin Jingang Nonwoven Co., Ltd. have been committed to technological innovation and quality control for over 26 years. By developing advanced German-style spunbond technology and integrating automated production lines, they ensure not only consistent product performance but also more efficient resource use. Their approach emphasizes flexible customization, systematic quality checks, and reliable delivery, all of which contribute to reducing environmental impact while meeting industrial and consumer requirements.

Product Lifecycle and Recyclability

Sustainable practices extend to the lifecycle of the products. Proper design, durability, and recyclability ensure that printed PP nonwoven fabrics can be reused or repurposed, reducing overall waste. Manufacturers increasingly provide guidance and technical support to clients on environmentally responsible applications, helping industries adopt green practices without compromising product functionality.

By combining advanced production technologies, eco-friendly materials, and strategic operational practices, the printed PP nonwoven fabric industry can deliver solutions that are not only practical and visually appealing but also aligned with global sustainability goals. Jiangyin Jingang Nonwoven Co., Ltd. exemplifies how commitment to innovation, quality, and environmental responsibility can position a manufacturer as a leader in sustainable nonwoven solutions.

English

English  русский

русский  Español

Español