The global demand for nonwoven fabrics continues to surge, driven by diverse applications from medical supplies to automotive interiors. At the heart of this industry lies the sophisticated non woven fabric making machine. This guide delves deep into the technology, processes, and critical considerations for selecting the right machinery, drawing from both industry expertise and established engineering principles.

Understanding Non Woven Fabric Making Technology

Nonwoven fabrics are manufactured by bonding or interlocking fibers through mechanical, chemical, thermal, or solvent means. Unlike weaving or knitting, this process bypasses the yarn production stage, allowing for high-speed, cost-effective production of fabrics with specific properties. The core of this production is the integrated production line, which typically involves several key stages.

Key Stages in a Production Line

1. Polymer Feeding & Extrusion

- Raw polymer granules (like PP or PET) are fed into an extruder.

- The material is melted into a homogeneous polymer melt.

- Precise temperature control is critical for fiber quality.

2. Fiber Formation

- For spunbond processes, molten polymer is forced through spinnerets to form continuous filaments.

- For meltblown processes, high-velocity air attenuates the polymer stream into micro-diameter fibers.

- This stage defines the fabric's basic fiber structure.

3. Web Formation

- Filaments or fibers are laid randomly or in a directed manner onto a moving conveyor belt.

- Techniques include air-laying, wet-laying, or direct laying from spinnerets.

- The uniformity here determines the fabric's consistency.

4. Bonding

- The loose web is consolidated to achieve strength. Common methods include:

- Thermal Bonding: Using heat and pressure through calender rollers.

- Chemical Bonding: Applying binders.

- Mechanical Bonding: Needle punching or hydroentangling.

5. Finishing & Winding

- The fabric may undergo treatments for wettability, color, or flame resistance.

- Finally, it is wound into large jumbo rolls for further conversion.

Exploring Different Types of Production Machinery

Selecting the correct type of machine depends entirely on the desired fabric characteristics and end-use. The main technologies offer distinct advantages.

Spunbond Nonwoven Machine

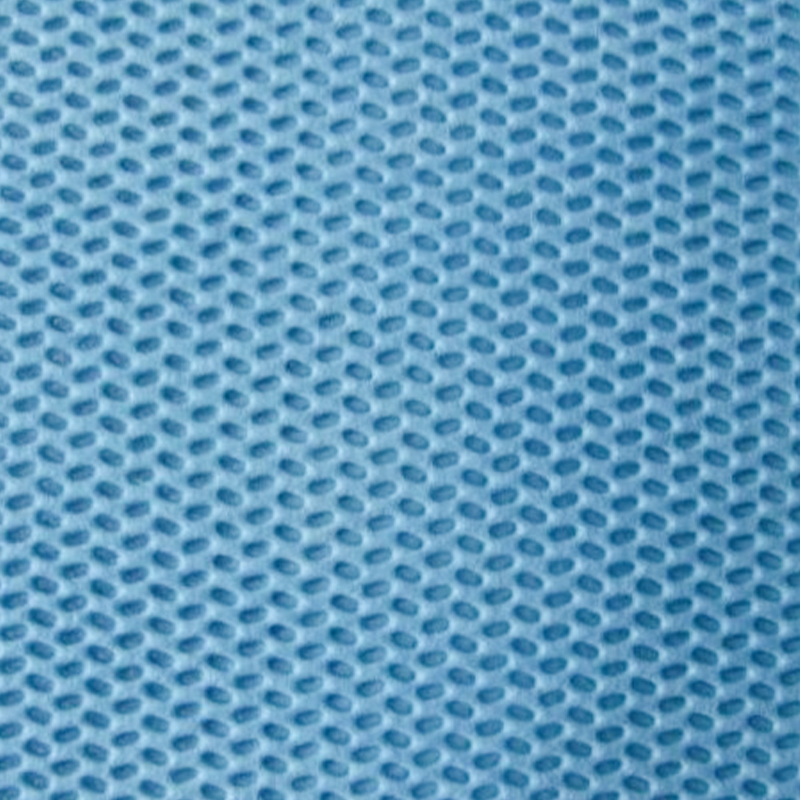

This system produces continuous filament webs, resulting in strong, uniform fabrics with excellent coverage. Spunbond fabrics are known for their balance of strength and softness, making them ideal for applications like geotextiles, carpet backing, and hygiene products.

Meltblown Nonwoven Machine

Meltblown machines are specialized for creating ultra-fine fiber webs with exceptional filtration and barrier properties. The key difference lies in the fiber formation process. The primary difference between spunbond and meltblown machines is the fiber diameter and resulting fabric functionality. Spunbond produces stronger, more durable sheets, while meltblown creates superior filtering layers. This is why they are often combined in SMS (Spunbond-Meltblown-Spunbond) composites for medical gowns and high-performance masks.

The comparison can be summarized as follows:

| Feature | Spunbond Machine | Meltblown Machine |

|---|---|---|

| Fiber Type | Continuous Filaments | Micro/Ultra-fine Fibers |

| Typical Fiber Diameter | 15 - 35 microns | 1 - 5 microns |

| Key Fabric Property | Tensile Strength, Durability | Filtration Efficiency, Barrier |

| Common Applications | Agriculture covers, Packaging, Hygiene outer layers | Air & Liquid Filters, Medical Mask filter layer, Insulation |

| Production Speed | Very High | Moderate to High |

Needle Punching Machine

This method uses barbed needles to mechanically interlock a dry-laid fiber web. It creates dense, felt-like fabrics valued for their thickness, resilience, and sound absorption. Common uses include automotive trunk liners, geotextiles, and synthetic leather substrates.

Hydroentangling Machine (Spunlace)

Also known as spunlace, this process uses high-pressure water jets to entangle fibers. It produces fabrics that are exceptionally soft, absorbent, and textile-like without using binders. These are widely used in wipes, medical drapes, and premium hygiene products.

Critical Factors for Choosing the Right Machine

Investing in a non woven fabric making machine is a significant decision. Beyond the core technology, several operational and business factors must be weighed to ensure a profitable and sustainable operation.

Assessing Your Production Requirements

- Target Fabric: Define the exact GSM (gram per square meter), width, strength, and texture needed.

- Annual Output: Estimate required capacity in tons/year to determine machine size and speed.

- Raw Material: Compatibility with PP, PET, bicomponent fibers, or other polymers.

Key Machine Specifications to Scrutinize

- Working Width: Dictates the final fabric roll width.

- Production Speed: Directly impacts output and ROI.

- Automation Level: Affects labor costs, consistency, and ease of operation.

- Energy Consumption: A major operational cost center; efficient designs are crucial.

Cost Considerations: Investment vs. Operational Expense

A comprehensive cost analysis is vital. Evaluating the total cost of ownership for a nonwoven machine involves balancing the initial capital outlay against long-term operational efficiency. A cheaper machine with high energy consumption and downtime may cost more over five years than a premium, efficient model.

| Cost Component | Lower-Cost Machine Typical Profile | Higher-Efficiency Machine Typical Profile |

|---|---|---|

| Initial Investment | Lower | Higher |

| Energy Consumption per ton | Higher | Significantly Lower |

| Maintenance Frequency & Cost | Higher | Lower (with predictive features) |

| Production Consistency & Yield | Variable, potentially more waste | High, less material waste |

| Long-term (5-year) Total Cost | Often Higher | Often Lower |

This underscores the importance of looking beyond the purchase price. For businesses focused on producing high-quality filtration media, understanding the nuances of a meltblown machine for filtration material production is particularly critical, as even minor inconsistencies can drastically impact filter efficiency [1].

Optimizing Production and Troubleshooting Common Issues

Maximizing the efficiency and output quality of your production line requires proactive optimization and an understanding of common challenges.

Optimizing for High-Volume PP Spunbond Nonwoven

Polypropylene (PP) spunbond is one of the most common nonwovens. Optimization focuses on:

- Extruder Temperature Profile: Precise zones ensure perfect melt uniformity.

- Spin Beam Maintenance: Clean spinnerets prevent drips and ensure uniform filament diameter.

- Bonding Calender Pressure & Temperature: Fine-tuning these is key to achieving the desired softness and strength balance for high-volume PP spunbond nonwoven production.

Addressing Frequent Machine Challenges

- Web Uniformity Issues: Often caused by clogged spinnerets, uneven air suction, or conveyor belt irregularities.

- Weak Fabric Tensile Strength: Can result from improper bonding temperature, insufficient pressure, or incorrect polymer mix.

- High Energy Consumption: May stem from inefficient heater bands, poor insulation, or outdated motor drives. Implementing an energy-saving nonwoven production line setup with modern variable frequency drives (VFDs) and heat recovery systems can reduce costs by 15-25% [2].

Maintenance and Longevity of Your Equipment

Regular, preventative maintenance is non-negotiable for minimizing downtime, ensuring product quality, and protecting your capital investment.

Essential Preventative Maintenance Schedule

- Daily: Visual inspections, cleaning of air filters and lint.

- Weekly: Checking belt alignments, lubricating guide rails and bearings.

- Monthly: Inspecting and cleaning spinnerets (for spunbond/meltblown), verifying sensor calibrations.

- Annually: Comprehensive system audit, motor servicing, and control system software updates.

Ensuring Durability and Performance

The longevity of a machine is built on its design and upkeep. Key durability factors include:

- Construction Quality: Use of hardened steel for critical components like calender rollers and spinnerets.

- Corrosion Resistance: Special coatings or stainless-steel parts in areas exposed to heat or chemicals.

- System Integration: A well-integrated automated nonwoven fabric manufacturing system with synchronized controls reduces mechanical stress and wear on individual components.

Following a rigorous maintenance guide for nonwoven machinery provided by the manufacturer is paramount to achieving the machine's full operational lifespan, which can exceed 15-20 years with proper care.

FAQs: Your Questions Answered

1. What is the main difference between spunbond and meltblown nonwoven machines?

The core difference lies in fiber formation. Spunbond machines stretch the polymer to form continuous filaments, creating strong, durable fabrics. Meltblown machines use high-speed air to blow the molten polymer into ultrafine, micro-diameter fibers, creating fabrics with superior filtration and barrier properties. They are often used in combination.

2. How do I choose between a needle punch and a hydroentangling (spunlace) machine?

Choose needle punching for thicker, denser, and more resilient fabrics like felts, automotive padding, or geotextiles. Opt for hydroentangling when you need a very soft, drapeable, absorbent, and binder-free fabric, such as for high-end wipes or medical dressings.

3. What are the most critical factors for reducing energy consumption in a nonwoven line?

Key factors include using high-efficiency motors with VFDs, implementing heat recovery systems from extruders and ovens, ensuring optimal insulation on heated components, and regularly maintaining air handling systems to reduce pressure drops.

4. How often does the key forming component (like a spinneret) need replacement?

With proper maintenance and cleaning, a high-quality spinneret can last for several years. However, specific parts like capillary plates may require refurbishment or replacement if damage or excessive wear affects fiber uniformity. The lifespan heavily depends on polymer type, production hours, and maintenance protocols.

5. Can one production line be configured to produce multiple types of nonwoven fabric?

Some advanced composite lines, like SMS (Spunbond-Meltblown-Spunbond), are designed for multi-layer production. However, converting a dedicated spunbond line to produce meltblown fabric, or vice versa, is generally not feasible due to fundamental differences in fiber-forming technology. Flexibility often comes from line configurations that combine these technologies from the outset.

Navigating the world of non woven fabric making machine technology requires a careful balance of technical understanding and practical business acumen. From selecting the right technology—be it for robust high-volume PP spunbond nonwoven production or specialized meltblown machine for filtration material production—to implementing an energy-saving nonwoven production line setup, each decision impacts profitability. Embracing an automated nonwoven fabric manufacturing system and adhering to a strict maintenance guide for nonwoven machinery are proven strategies for ensuring long-term competitiveness and equipment longevity. As a company deeply integrated in this field, Jiangyin Jingang Nonwoven Co., Ltd. understands that the right machinery is the foundation for innovation and quality in the ever-evolving nonwoven industry.

References

[1] Hutten, I. M. (2007). *Handbook of Nonwoven Filter Media*. Oxford: Elsevier Ltd. (Reference for the impact of process consistency on filtration efficiency).

[2] Russell, S. J. (Ed.). (2007). *Handbook of Nonwovens*. Cambridge: Woodhead Publishing Ltd. (Reference for energy-saving technologies and practices in nonwoven production).

English

English  русский

русский  Español

Español