The global demand for synthetic textiles has driven significant innovations in thermoplastic polymer extrusion. At the heart of this industrial shift is the PP non-woven fabric mak...

READ MORECustom CNC Glass Processing Equipment Manufacturers

-

Automatic Horizontal CNC Shaped Glass Edge Grinding Machine

The CNC special-shaped glass edge grinding processing center is a device that focuses on glass product processing, especially good at glass edge grind...

-

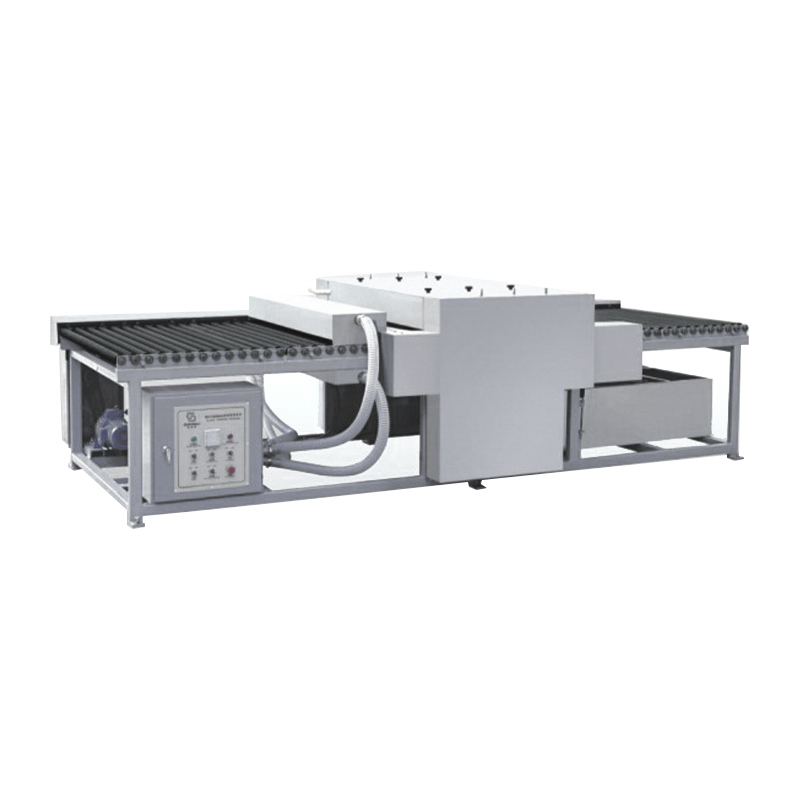

JG-1200 Horizontal Glass Washing Machine

As a glass deep processing equipment, the horizontal glass washing machine focuses on cleaning and drying the glass surface. The equipment adopts a ho...

-

Glass Film Lamination Machine

A glass film laminating machine is a kind of equipment specially used for various types of flat monolithic glass and hollow glass products, which can ...

-

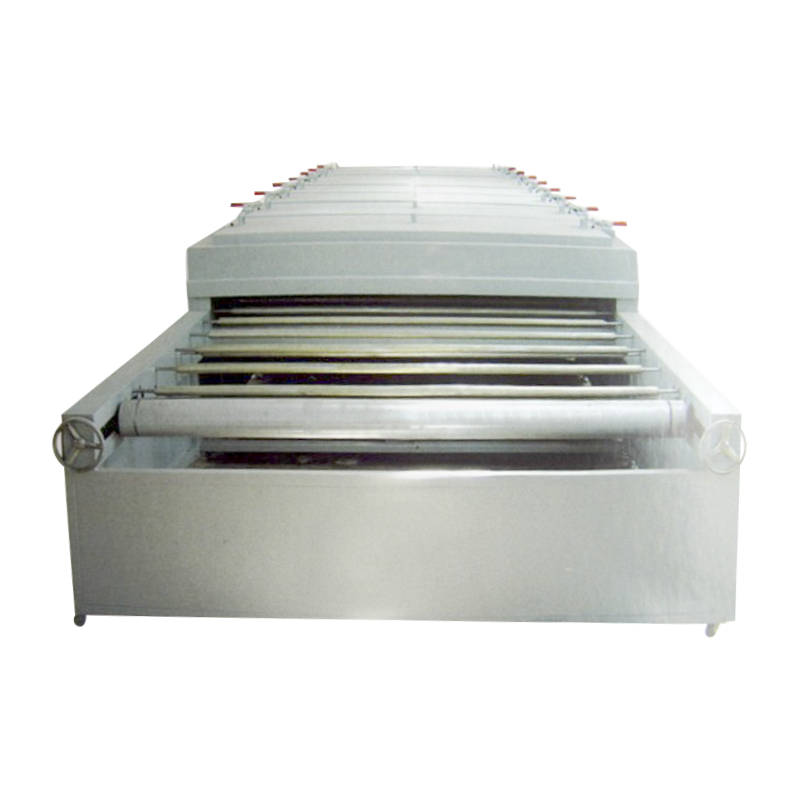

Color Crystal Glass Oven Drying Tunnel

The colored crystal glass oven is specially designed for the drying needs of colored crystal glass. Through a scientific internal structure and a prec...

-

Semi-automatic Flat 3D Glass Screen Printing Machine

The flat semi-automatic 3D glass screen printer is designed for precise screen printing on 3D glass surfaces. The overall structure of the equipment i...

Jiangyin Jingang Nonwoven Co., Ltd. is a professional enterprise focusing on the manufacture of nonwoven fabrics and glass deep processing equipment. Its glass deep processing equipment has a high technical level and a wide range of application scenarios in the industry. The company mainly produces CNC special-shaped glass edge grinding processing center, Caijing glass screen printing machine, glass washing machine, glass drying oven, glass transfer table and other equipment. These equipment are widely used in the field of glass deep processing, such as edge grinding, polishing, hole opening, grooving and other processes.

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. is

China Custom CNC Glass Processing Equipment Manufacturers and

CNC Glass Processing Equipment Suppliers.Jingang is a professional enterprise specializing in the research, development, and manufacturing of nonwoven materials and supporting equipment. Located in Jiangyin, Jiangsu Province, China, the company offers a wide range of products including PP spunbond and meltblown nonwovens, which are widely used in industries such as automotive, agriculture, packaging, and deep glass processing.In addition to nonwoven materials, we independently design and manufacture a variety of specialized machinery, including nonwoven production lines, CNC glass edging machines, and printing equipment—dedicated to providing customers with systematic and automated production solutions.

Over the past 26 years, we have remained committed to technological innovation and quality control. In 2002, we successfully developed German-style spunbond technology, improving the stability and efficiency of domestically produced equipment. In 2009, we launched CNC edging machines for shaped glass, expanding the application scope of glass processing. These milestones have played a key role in positioning our company at the forefront of the industry.

We have established a sound quality management system and strictly implement multi-stage inspection processes to ensure our products meet international standards. Through flexible customization, professional technical support, and reliable delivery capabilities, Jiangyin Jingang has built long-term partnerships with clients at home and abroad, earning a solid reputation in the market.We will continue to provide reliable products, strong technical expertise, and practical services to deliver more efficient and sustainable solutions to customers around the world.

-

-

In the evolving landscape of sustainable textiles, Checkered PP Non-Woven Fabric has emerged as a high-performance material that bridges the gap between aesthetic appeal and struct...

READ MORE -

Sesame Pattern PP Non-Woven Fabric, characterized by its distinctive textured surface resembling sesame seeds, is a specialized variant of polypropylene non-woven material. Its uni...

READ MORE -

In the vast landscape of industrial textiles, PP Spunbond Non Woven Fabric stands as a cornerstone material, prized for its versatility, durability, and cost-effectiveness. As a do...

READ MORE -

In the modern manufacturing landscape, precision, efficiency, and versatility are paramount. For industries ranging from automotive to architecture, the ability to cut, shape, and ...

READ MORE

Advancements in CNC Glass Processing Equipment: Enhancing Precision and Efficiency

CNC glass processing equipment has revolutionized the glass manufacturing industry by combining precision engineering, automated control, and intelligent software to handle complex tasks such as cutting, edging, shaping, drilling, and polishing. The adoption of CNC technology has allowed manufacturers to achieve consistent quality, higher production efficiency, and reduced material waste, which are essential in today’s competitive industrial environment.

Over the years, significant advancements have been made in CNC glass processing technology. Modern machines now utilize multi-axis control systems that enable precise movement along X, Y, Z, and rotational axes, allowing for intricate shapes and customized glass products. High-speed spindles, reinforced guide rails, and optimized drive systems improve cutting accuracy while reducing vibration and wear. Additionally, the integration of intelligent software provides real-time monitoring, adaptive processing, and predictive maintenance, which together enhance machine reliability and minimize downtime.

Jiangyin Jingang Nonwoven Co., Ltd., founded in 1999, has been a pioneer in applying CNC technology to glass processing machinery. Since the launch of their CNC edging machines for shaped glass in 2009, the company has enabled manufacturers to produce complex glass components with high consistency and efficiency. Beyond precision cutting, these machines support multi-functional operations such as bevelling, polishing, and hole drilling, all in a single automated workflow, which significantly reduces manual intervention and production time.

Another important development in CNC glass processing is the move toward smart automation. Modern systems incorporate IoT-enabled sensors, cloud-based data analytics, and machine learning algorithms to optimize processing parameters in real time. This not only improves product quality but also extends equipment life by reducing mechanical stress and predicting maintenance needs before failures occur. These intelligent features empower manufacturers to respond quickly to changing production requirements and reduce operational costs.

The impact of these advancements is especially notable in industries such as automotive, architecture, and specialty glass production, where precision, speed, and reliability are critical. Manufacturers benefit from lower material waste, faster turnaround times, and the ability to produce highly customized products that meet exacting standards. Jiangyin Jingang Nonwoven Co., Ltd. continues to leverage its extensive experience in machinery design and technological innovation to offer comprehensive solutions, helping clients achieve more efficient, sustainable, and cost-effective glass processing workflows.

Looking forward, the future of CNC glass processing will likely focus on even greater automation, energy efficiency, and integration with smart manufacturing ecosystems. Advancements in robotics, AI-driven quality control, and adaptive cutting technologies are expected to further enhance precision and productivity, ensuring that CNC glass processing remains a key driver of industrial innovation.

Selecting the Right CNC Glass Processing Equipment for Industrial Applications

Choosing the appropriate CNC glass processing equipment is critical for manufacturers aiming to balance precision, efficiency, and cost-effectiveness in industrial operations. With the rapid advancements in CNC technology, machines now offer a wide range of capabilities, from basic edge grinding and cutting to complex shaping, drilling, and polishing. Understanding the specific requirements of your production line is the first step in selecting the right equipment.

Key factors to consider include the types of glass to be processed, the desired shapes and sizes, production volume, and the level of automation required. For instance, thicker or tempered glass may require machines with stronger spindles, reinforced guides, and advanced cooling systems, while intricate designs demand multi-axis control and high-precision linear drives. Additionally, manufacturers should consider the flexibility of the equipment to handle varying product specifications without extensive reconfiguration.

Jiangyin Jingang Nonwoven Co., Ltd. has extensive experience in designing CNC glass processing machinery tailored to industrial needs. Since launching their CNC edging machines for shaped glass in 2009, the company has focused on delivering systems that combine high precision, automation, and operational reliability. Their machines are capable of performing multiple operations—including cutting, edging, polishing, and hole drilling—within a single automated workflow, reducing production time and minimizing human error.

Another crucial consideration is software integration. Modern CNC machines are equipped with intelligent control systems that allow for precise programming, real-time monitoring, and adaptive adjustments. Features such as predictive maintenance alerts, automated tool compensation, and optimized cutting paths can improve productivity, extend machine lifespan, and reduce material waste. These capabilities are particularly valuable in high-volume industrial settings where consistency and efficiency are paramount.

Maintenance and technical support also play a significant role in equipment selection. Reliable after-sales service, readily available spare parts, and professional technical guidance ensure that machines operate smoothly over long production cycles. Jiangyin Jingang Nonwoven Co., Ltd. provides comprehensive support alongside their CNC glass processing systems, helping clients maximize machine performance and maintain high production standards.

Ultimately, selecting the right CNC glass processing equipment requires a careful assessment of production goals, material types, operational flexibility, and technological features. By considering these factors, manufacturers can invest in machinery that not only meets current production demands but also adapts to future needs, enhancing overall efficiency, precision, and competitiveness in the glass processing industry.

English

English  русский

русский  Español

Español