The global demand for synthetic textiles has driven significant innovations in thermoplastic polymer...

Read MoreSemi-automatic Flat 3D Glass Screen Printing Machine

The flat semi-automatic 3D glass screen printer is designed for precise screen printing on 3D glass surfaces. The overall structure of the equipment is compact and reasonable, integrating mechanical transmission and automatic control technology. Through the precisely controlled screen printing components, various ink patterns can be accurately transferred to the 3D glass surface, giving the glass rich visual effects and functional characteristics, meeting the diverse needs of different industries for glass appearance and performance.

- Describe

- Implementation Standards

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. is China Semi-automatic Flat 3D Glass Screen Printing Machine Factory and Wholesale Semi-automatic Flat 3D Glass Screen Printing Machine Company.Jiangyin is a professional enterprise specializing in the research, development, and manufacturing of nonwoven materials and supporting equipment. Located in Jiangyin, Jiangsu Province, China, the company offers a wide range of products including PP spunbond and meltblown nonwovens, which are widely used in industries such as automotive, agriculture, packaging, and deep glass processing.In addition to nonwoven materials, we independently design and manufacture a variety of specialized machinery, including nonwoven production lines, CNC glass edging machines, and printing equipment—dedicated to providing customers with systematic and automated production solutions.

-

-

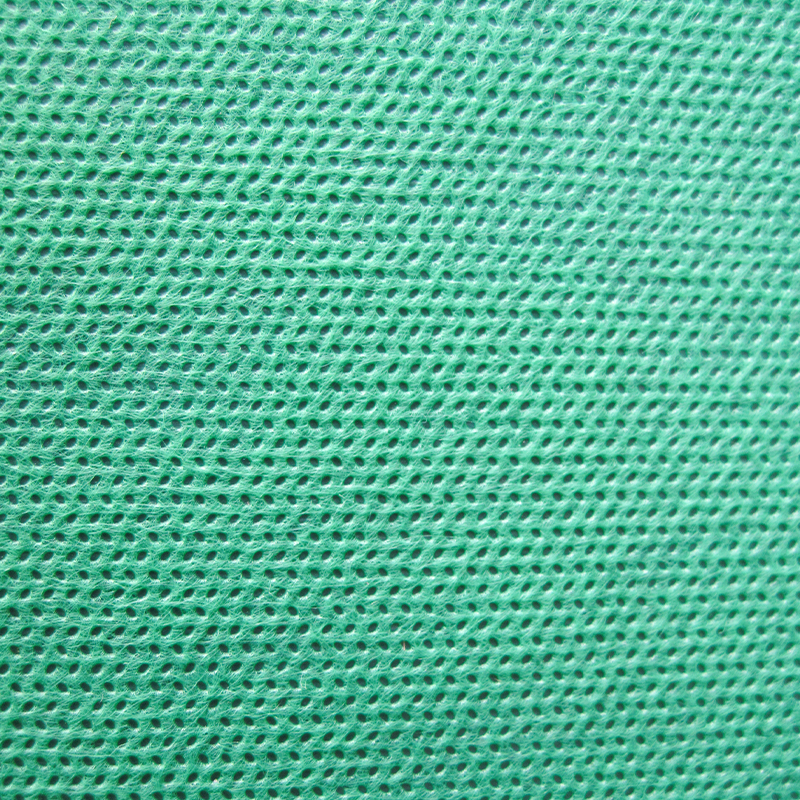

In the evolving landscape of sustainable textiles, Checkered PP Non-Woven Fabric has emerged as a hi...

Read More -

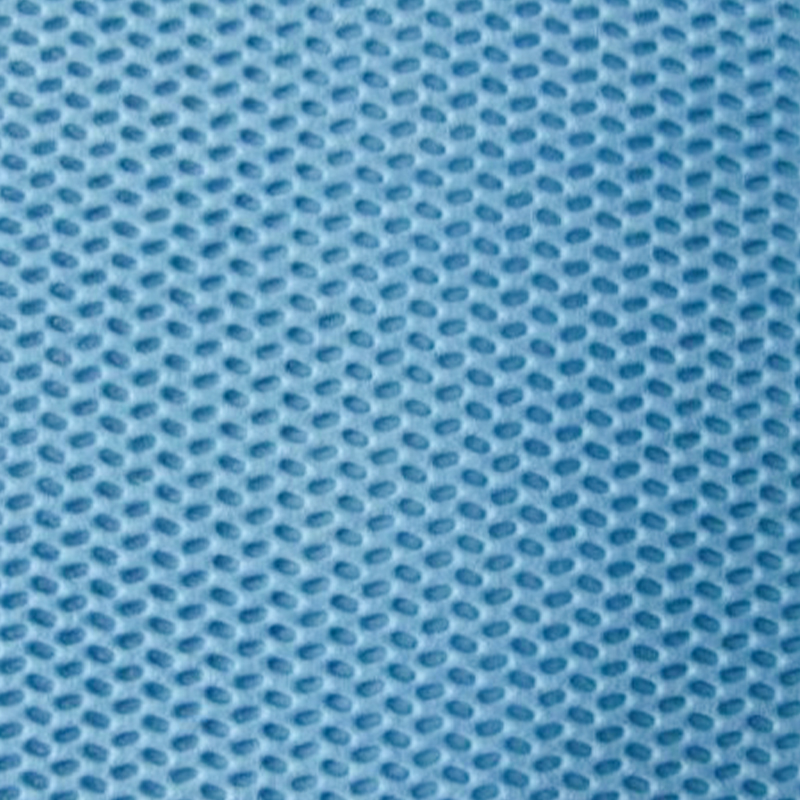

Sesame Pattern PP Non-Woven Fabric, characterized by its distinctive textured surface resembling ses...

Read More -

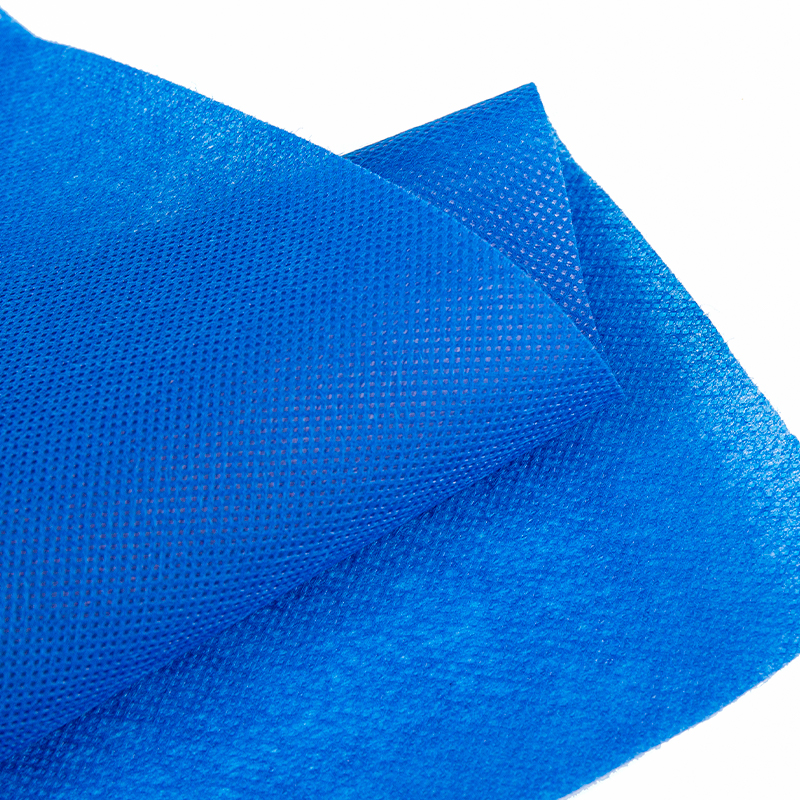

In the vast landscape of industrial textiles, PP Spunbond Non Woven Fabric stands as a cornerstone m...

Read More -

In the modern manufacturing landscape, precision, efficiency, and versatility are paramount. For ind...

Read More -

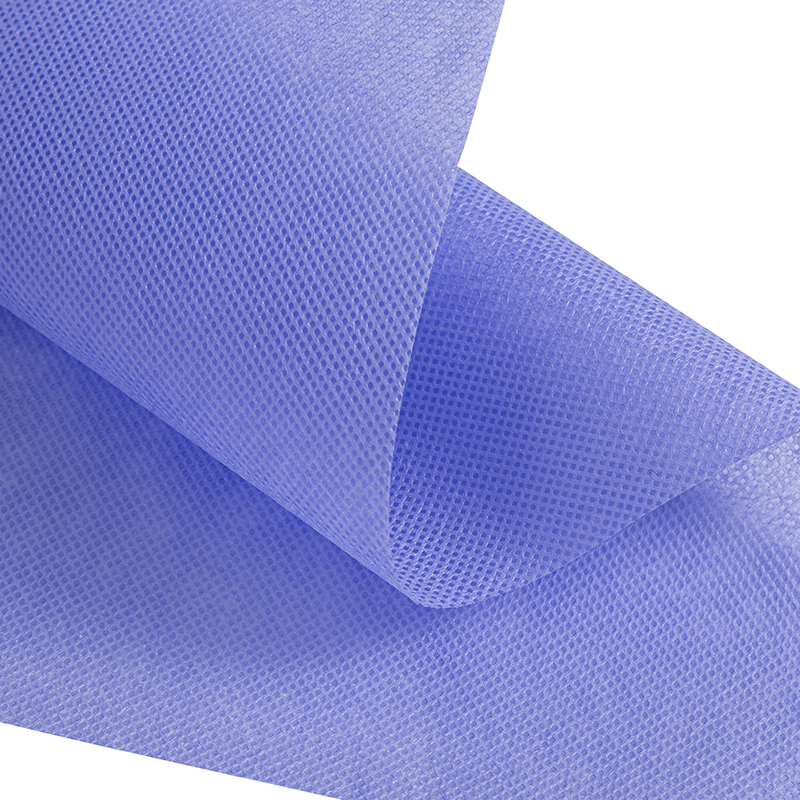

Understanding the Non-Woven Landscape The world of non-woven fabrics is vast and diverse, offering a...

Read More

English

English  русский

русский  Español

Español