The global demand for synthetic textiles has driven significant innovations in thermoplastic polymer extrusion. At the heart of this industrial shift is the PP non-woven fabric mak...

READ MORECustom PP Non Woven Fabric Making Machine Manufacturers

-

1.6m PP Spunbond Nonwoven Fabric Production Line

PP spun Bund non-woven fabric machines (1.6 meters) should include all the parts & items as listed below. 1. Screw extruder ¢135 1 set (1)Length ...

-

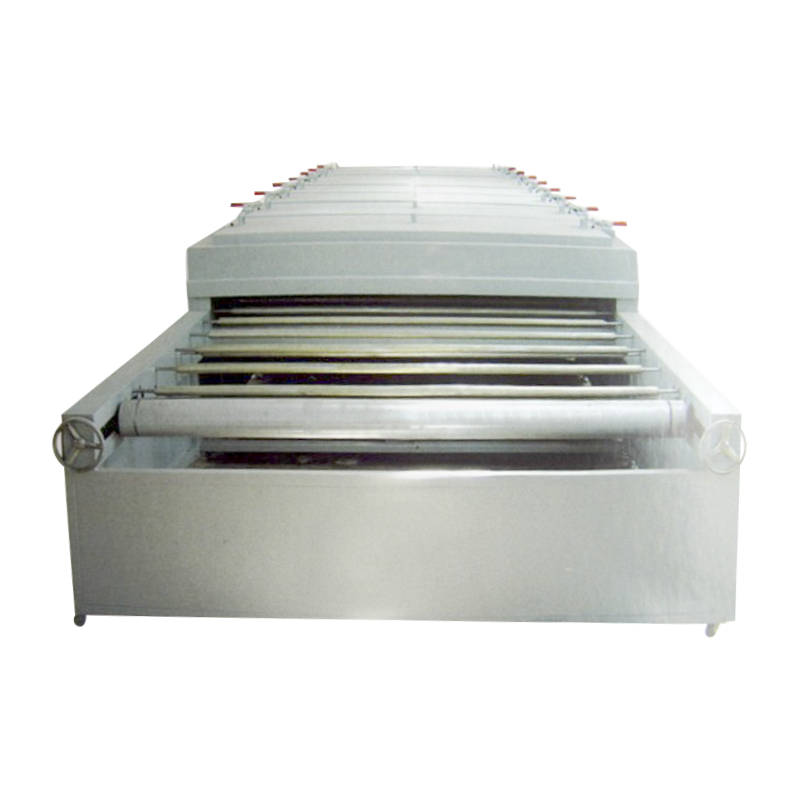

2.4m PP Spunbond Non Woven Fabric Production Line

PP spun Bund non-woven fabric machines (2.4 meters) should include all the parts & items as it is listed below. 1. Screw extruder ¢150 1 set(1)Le...

-

3.2m PP Spunbond Nonwoven Fabric Machine

PP spun Bund non-woven fabric machines (3.2 meters) should include all the parts & items as it is listed below. 1. Screw extruder ¢180 1 set (1)Le...

The polypropylene non-woven fabric equipment melts and extrudes polypropylene (PP) slices to form a spinning, and then reinforces it through processes such as web forming, hot rolling or needle punching, and finally makes a non-woven fabric product with high strength, high temperature resistance, aging resistance, antistatic and other functions. Its production process usually includes the following key steps: Raw material processing: Polypropylene slices are melted and extruded at high temperature through a large screw, and impurities are removed through a filter to ensure the quality of spinning. Spinning and cooling: The molten polymer is extruded into filaments through the spinning box and spinneret, and then quickly cooled and solidified in the cooling system to form a fiber mesh structure. Web forming and reinforcement: The cooled filament bundles are laid into a mesh by a web laying machine, and then reinforced by a hot rolling machine or needle punching equipment to enhance its physical properties. Slitting and winding: The reinforced non-woven fabric is cut into the required width by a slitting machine, and then rolled into a roll by a winder for subsequent processing or packaging.

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. is

China Custom PP Non Woven Fabric Making Machine Manufacturers and

PP Non Woven Fabric Making Machine Suppliers.Jingang is a professional enterprise specializing in the research, development, and manufacturing of nonwoven materials and supporting equipment. Located in Jiangyin, Jiangsu Province, China, the company offers a wide range of products including PP spunbond and meltblown nonwovens, which are widely used in industries such as automotive, agriculture, packaging, and deep glass processing.In addition to nonwoven materials, we independently design and manufacture a variety of specialized machinery, including nonwoven production lines, CNC glass edging machines, and printing equipment—dedicated to providing customers with systematic and automated production solutions.

Over the past 26 years, we have remained committed to technological innovation and quality control. In 2002, we successfully developed German-style spunbond technology, improving the stability and efficiency of domestically produced equipment. In 2009, we launched CNC edging machines for shaped glass, expanding the application scope of glass processing. These milestones have played a key role in positioning our company at the forefront of the industry.

We have established a sound quality management system and strictly implement multi-stage inspection processes to ensure our products meet international standards. Through flexible customization, professional technical support, and reliable delivery capabilities, Jiangyin Jingang has built long-term partnerships with clients at home and abroad, earning a solid reputation in the market.We will continue to provide reliable products, strong technical expertise, and practical services to deliver more efficient and sustainable solutions to customers around the world.

-

-

In the evolving landscape of sustainable textiles, Checkered PP Non-Woven Fabric has emerged as a high-performance material that bridges the gap between aesthetic appeal and struct...

READ MORE -

Sesame Pattern PP Non-Woven Fabric, characterized by its distinctive textured surface resembling sesame seeds, is a specialized variant of polypropylene non-woven material. Its uni...

READ MORE -

In the vast landscape of industrial textiles, PP Spunbond Non Woven Fabric stands as a cornerstone material, prized for its versatility, durability, and cost-effectiveness. As a do...

READ MORE -

In the modern manufacturing landscape, precision, efficiency, and versatility are paramount. For industries ranging from automotive to architecture, the ability to cut, shape, and ...

READ MORE

Maintenance and Troubleshooting Tips for PP Non Woven Fabric Making Equipment

Proper maintenance and troubleshooting of PP non woven fabric making equipment are essential for stable production, high-quality output, and extended machinery lifespan. Jiangyin Jingang Nonwoven Co., Ltd., with over 26 years of experience in nonwoven materials and equipment manufacturing, emphasizes systematic care, preventive maintenance, and rapid troubleshooting to ensure operational efficiency and safety.

1. Routine Maintenance Practices

Regular inspection and upkeep are crucial to prevent unexpected breakdowns:

- Mechanical Components: Check rollers, bearings, belts, and gears for wear or misalignment. Lubricate moving parts according to the maintenance schedule to reduce friction.

- Electrical Systems: Inspect wiring, sensors, and control panels to prevent short circuits or signal failures. Ensure all safety switches function properly.

- Temperature & Pressure Control: Maintain consistent temperature in the extruder and uniform pressure in the forming section to ensure even fiber distribution.

- Conveyor and Collection System: Monitor belt tension and alignment to avoid fabric tearing or misplacement.

2. Cleaning and Environmental Considerations

Keeping equipment and production areas clean prevents contamination and machinery malfunctions:

- Remove dust, fiber debris, and residual polymer from the extruder die, rollers, and conveyor systems regularly.

- Ensure proper ventilation to minimize heat accumulation and maintain stable production conditions.

- For applications in medical, packaging, or automotive sectors, strictly follow hygiene protocols to maintain fabric quality.

3. Troubleshooting Common Issues

Understanding common problems and their causes helps reduce downtime:

- Inconsistent Fabric Thickness: Often caused by uneven feed rates, temperature fluctuations, or worn extrusion components.

- Fabric Tearing: May result from improper tension, damaged rollers, or foreign objects interfering with the fabric path.

- Excessive Vibrations or Noise: Usually indicates misaligned shafts, unbalanced rollers, or loose mechanical connections.

- Electrical or Sensor Failures: Check wiring, connections, and sensors; ensure control system firmware is up to date.

4. Upgrades and Technical Support

Jiangyin Jingang Nonwoven Co., Ltd. offers advanced technical solutions to enhance equipment performance:

- German-style spunbond technology for stable and high-efficiency production.

- Customized nonwoven production lines with integrated automation to reduce labor costs.

- Professional technical guidance for preventive maintenance and troubleshooting procedures.

- Optional CNC glass edging and printing equipment integration for diversified production capabilities.

5. Key Equipment Parameters

| Parameter | Typical Range / Specification | Notes |

|---|---|---|

| Spunbond Line Width | 1.6–3.2 m | Depends on production capacity and fabric width requirements |

| Production Speed | 50–150 m/min | Adjustable according to material type and thickness |

| Fabric Weight | 10–200 g/m² | Controlled by extrusion rate and calender pressure |

| Extruder Temperature | 200–280 °C | Depends on PP grade and melt flow index |

| Roller Diameter | Ø300–Ø600 mm | Varies with machine model |

| Power Supply | 380 V / 50 Hz, Three-phase | Standard industrial power requirement |

| Automation Level | Semi-automatic / Fully automatic | Includes PLC control, tension control, and monitoring system |

By following routine maintenance, proper cleaning, and timely troubleshooting, manufacturers can ensure stable production, high-quality nonwoven fabrics, and longer equipment lifespan. Leveraging the technical expertise and customized solutions provided by Jiangyin Jingang Nonwoven Co., Ltd. allows enterprises to achieve efficient, reliable, and sustainable operations.

How to Optimize Production Efficiency with PP Non Woven Fabric Machines

Optimizing production efficiency in PP non woven fabric manufacturing requires a combination of advanced machinery, well-planned processes, and ongoing maintenance. Jiangyin Jingang Nonwoven Co., Ltd., with over 26 years of experience in nonwoven materials and equipment, provides expertise in designing high-performance production lines and supporting operational excellence.

1. Choosing the Right Equipment

Selecting a PP non woven fabric machine that aligns with your production goals is crucial. Consider factors such as:

- Production capacity and fabric width requirements

- Fabric weight range and thickness consistency

- Automation level, including PLC systems for precise control

- Energy efficiency and reliability of mechanical and electrical components

Jiangyin Jingang offers customized production lines and machinery that incorporate German-style spunbond technology, providing stable output and high efficiency.

2. Streamlining Production Processes

Efficient workflow is key to maximizing output:

- Ensure smooth material feeding and uniform fiber distribution.

- Maintain optimal extrusion temperature and pressure settings to minimize defects.

- Integrate inline monitoring and quality control to detect irregularities in real-time, reducing waste.

- Use automated tension and winding systems to accelerate handling and reduce manual intervention.

3. Regular Maintenance and Preventive Measures

Proper maintenance reduces downtime and improves machine longevity:

- Lubricate moving parts and inspect rollers, bearings, and belts regularly.

- Clean extrusion heads, conveyor belts, and die plates to prevent fiber buildup.

- Calibrate sensors and control systems to maintain consistent production parameters.

- Implement a preventive maintenance schedule based on usage intensity and operating conditions.

4. Optimizing Energy and Resource Use

Energy-efficient operations not only reduce costs but also support sustainability:

- Monitor electricity and compressed air consumption; adjust machine settings for minimal energy use without compromising output.

- Recycle offcuts and fabric scraps where possible to reduce waste.

- Use high-quality raw materials to minimize defects and reprocessing.

5. Workforce Training and Technical Support

Well-trained operators improve efficiency and reduce errors:

- Provide comprehensive training on machine operation, safety, and troubleshooting.

- Develop standard operating procedures (SOPs) for critical tasks.

- Leverage technical support from Jiangyin Jingang for optimization advice, upgrades, and problem-solving.

6. Continuous Improvement and Technology Upgrades

Stay competitive by adopting advanced technologies and process improvements:

- Consider automation upgrades, such as smart sensors and PLC integration, to enhance precision.

- Regularly review production data to identify bottlenecks and implement process adjustments.

- Explore new nonwoven technologies or machinery enhancements offered by Jiangyin Jingang to boost productivity.

Optimizing production efficiency with PP non woven fabric machines involves careful equipment selection, streamlined workflows, preventive maintenance, energy management, skilled operators, and continuous technological improvements. By applying these strategies and leveraging the expertise of Jiangyin Jingang Nonwoven Co., Ltd., manufacturers can achieve higher output, consistent quality, and sustainable operations.

English

English  русский

русский  Español

Español