The global demand for synthetic textiles has driven significant innovations in thermoplastic polymer...

Read More2.4m PP Spunbond Non Woven Fabric Production Line

PP spun Bund non-woven fabric machines (2.4 meters) should include all the parts & items as it is listed below.

1. Screw extruder ¢150 1 set

(1)Length dia percentage 1: 30

(2)Maximum rotational speed: 75r/Min

(3)Power: 110kw

(4)Frequency conversion governor

(5)Recycle extruder: match #90 screws for recycling waste edge, 15kw AC motor

2. Double tub continuous melting filter unit 1 set

(1)Melting area: 2.5m2 ×2;

(2)Maximum pressure: 12MPa

(3)The allowed pressure balance after melting: 6MPa

(4)The allowed pressure of the jacket: 0.25MPa

(5)Maximum temperature: 310℃

(6)Heat transfer medium and heating style: 350 °C or above, heat conduction oil, cyclic heating

(7)Filtering precious: 300um

(8)Material of the melt passing department is 1Cr18Ni9Ti; the material for the heating box is 16MnR.

3. Metering Pump 1pc Model No. YRA 1×250 (delivery capacity 250 each)

(1)Pressure of the exit: 40 MPa

(2)Rotate speed: 5-30r/min

(3)Maximum pressure balance: 35MPa

(4)Working temperature: ≤330℃

(5)Temperature for cleaning: ≤450℃

(6)Motor: 5.5kw, AC motor.

(7)Fuji frequency conversion governor

4. Spinneret 1pc (match spinneret board two pair)

(1)Heat conduction oil cyclic heating

(2)Maximum temperature: 300℃

5. Cooling and drawing system, two pcs

(1)Made of aluminum

(2)perforated plate, bending table, 60um stainless mesh, multi-ply melting

6. Drafting 1pc ( specification: 2850×2000×65)

7. Diffusion 1pc

8. Lapping machine 1pc

(1)Alternating current & governing motor, power 7.5 kW

(2)Frequency conversion governor

(3)Maximum speed: 120m/min

9. Thermo-bonded machine 1pc

(1)Roller: stiletto around, heat conduction, oil cyclic heating

(2)Oil lubricates the cooling bearing

(3)The exact temperature control is ±1℃

(4)Maximum speed: 120m/min

(5)Alternating current & governing motor, power 30 kW

(6)Frequency conversion governor

10. Rolling up machine 1pc

(1)Power: 11kw (Alternating current & governing motor)

(2)Maximum speed: 120m/min

(3)Frequency conversion governor

11. Slitting machine 1 pc

(1)AC motor, 5.5kw.

(2)Maximum speed: 150m/min

(3)Width in slitting: freely controlled

(4)Frequency conversion governor

12. Carrier air conditioner 1pc

13. Hot stove 4pcs(36kw 2pc, 48kw 1pc, 12kw 1pc)

(1)Design pressure: 10Kpa

(2)Working pressure: 3Kpa

(3)Design temperature: 300℃

(4)The temperature precision: ±1℃

(5)Power: 3kw for 36kw and 48kw hot stove, and 1.5kw for 12kw hot stove

(6)Designed discharge: 12.5m3/h

14. Blower fan two pcs (30kw)

(1)Design discharge: 14013 m3/h

(2)Design pressure: 4736pa

(3)Rotate speed: 1450r/min

(4)Power: 30kw

(5)Frequency conversion governor

15. Blow fan for smoke 1 pc

(1)Design discharge: 1410-1704 m3/h

(2)Design pressure: 3507-3253 pa

(3)Rotate speed: 2900r/min

(4)Power: 4kw

(5)Frequency conversion governor

16. Controlling system for electric 1 set (controlled by switch or touch screen, up to the buyer’s choice)

17. Air compressor 1 set

18. Material store tank 1 set 300KG

19. Feeder 1 set 10HP

20. Ultrasonic cleaner, ultrasonic wave cleaner 150000 1 set

(1)Dozer for master batch 200W 2sets

(2)Frequency conversion governor

21. Electric furnaces for cleaning 1set

22. Steel frame 10*10*6.5M 1set

23. Conveyor belt 4.15*10M 1piece

24. Electric host/lift 1 ton/set 2sets

25. Piping one suit

- Describe

- Implementation Standards

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. is China 2.4m PP Spunbond Non Woven Fabric Production Line Factory and Wholesale 2.4m PP Spunbond Non Woven Fabric Production Line Company.Jiangyin is a professional enterprise specializing in the research, development, and manufacturing of nonwoven materials and supporting equipment. Located in Jiangyin, Jiangsu Province, China, the company offers a wide range of products including PP spunbond and meltblown nonwovens, which are widely used in industries such as automotive, agriculture, packaging, and deep glass processing.In addition to nonwoven materials, we independently design and manufacture a variety of specialized machinery, including nonwoven production lines, CNC glass edging machines, and printing equipment—dedicated to providing customers with systematic and automated production solutions.

-

-

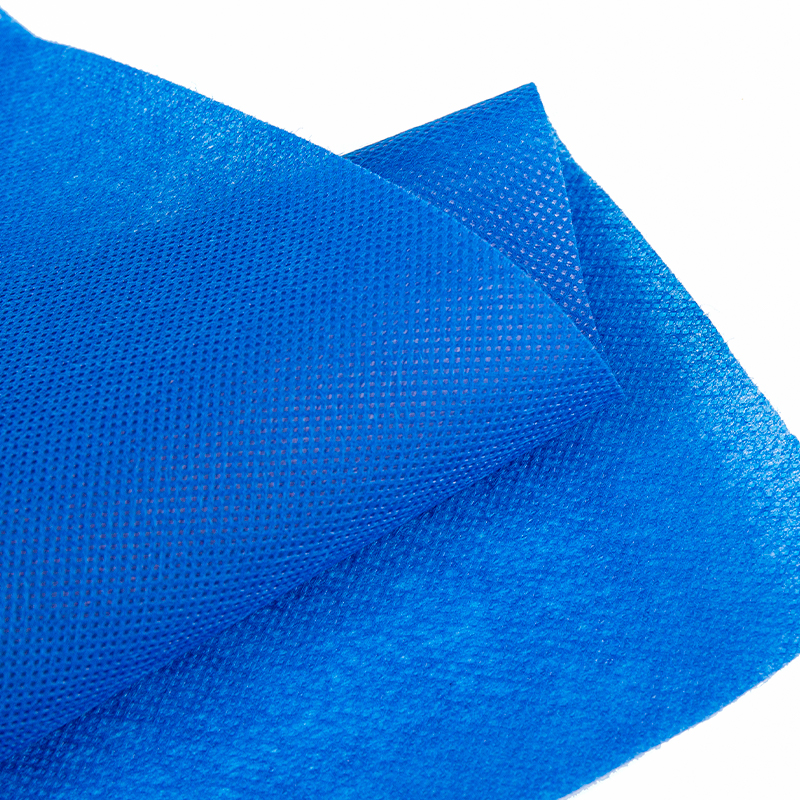

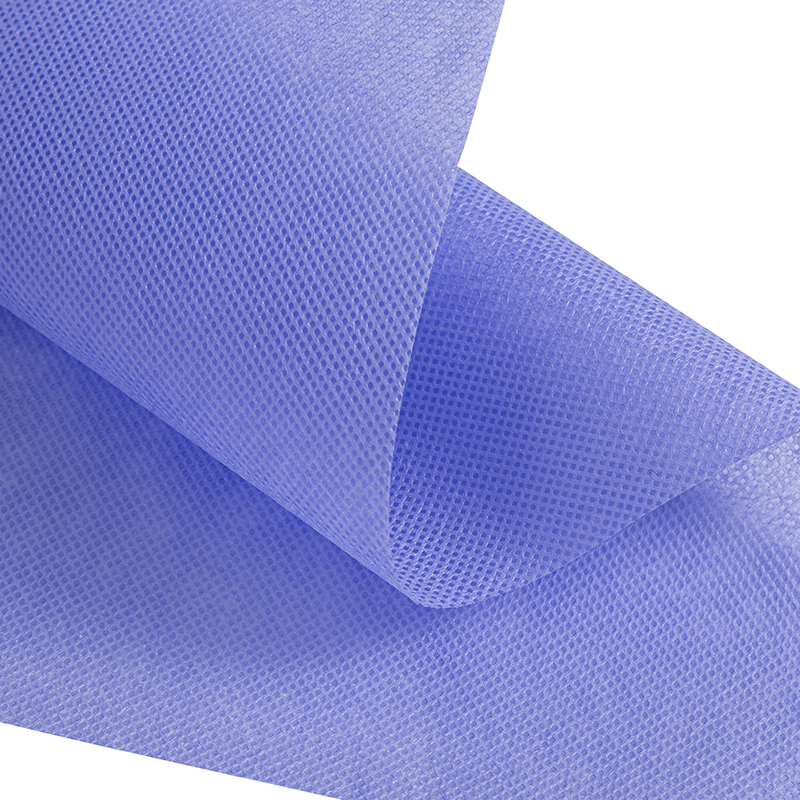

In the evolving landscape of sustainable textiles, Checkered PP Non-Woven Fabric has emerged as a hi...

Read More -

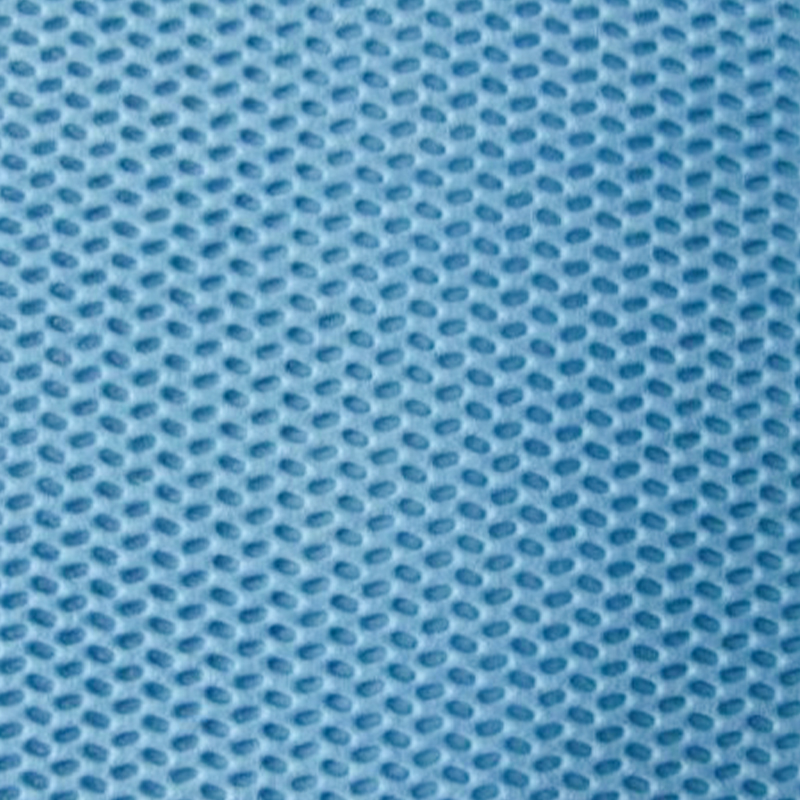

Sesame Pattern PP Non-Woven Fabric, characterized by its distinctive textured surface resembling ses...

Read More -

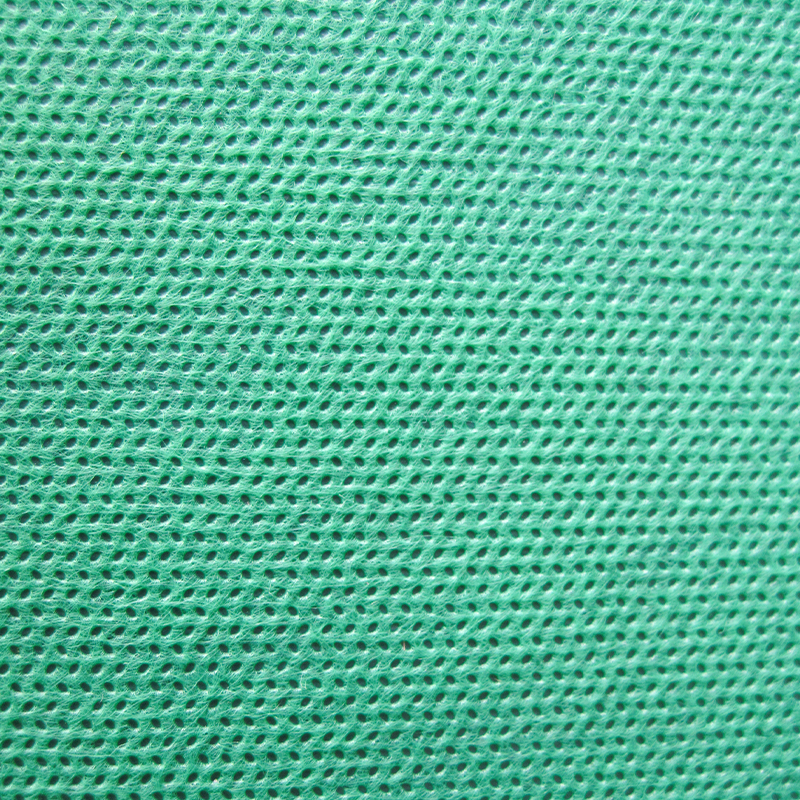

In the vast landscape of industrial textiles, PP Spunbond Non Woven Fabric stands as a cornerstone m...

Read More -

In the modern manufacturing landscape, precision, efficiency, and versatility are paramount. For ind...

Read More -

Understanding the Non-Woven Landscape The world of non-woven fabrics is vast and diverse, offering a...

Read More

English

English  русский

русский  Español

Español