The global demand for synthetic textiles has driven significant innovations in thermoplastic polymer extrusion. At the heart of this industrial shift is the PP non-woven fabric mak...

READ MORECustom Non Woven Fabric Making Machine, Glass Processing Equipment Manufacturers

-

1.6m PP Spunbond Nonwoven Fabric Production Line

PP spun Bund non-woven fabric machines (1.6 meters) should include all the parts & items as listed below. 1. Screw extruder ¢135 1 set (1)Length ...

-

2.4m PP Spunbond Non Woven Fabric Production Line

PP spun Bund non-woven fabric machines (2.4 meters) should include all the parts & items as it is listed below. 1. Screw extruder ¢150 1 set(1)Le...

-

3.2m PP Spunbond Nonwoven Fabric Machine

PP spun Bund non-woven fabric machines (3.2 meters) should include all the parts & items as it is listed below. 1. Screw extruder ¢180 1 set (1)Le...

-

Automatic Horizontal CNC Shaped Glass Edge Grinding Machine

The CNC special-shaped glass edge grinding processing center is a device that focuses on glass product processing, especially good at glass edge grind...

-

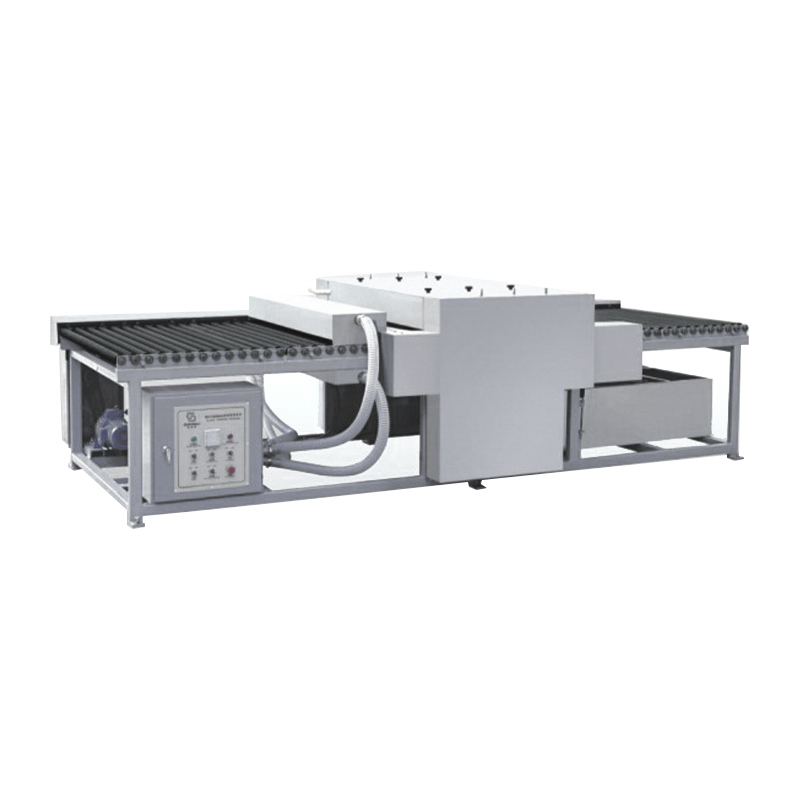

JG-1200 Horizontal Glass Washing Machine

As a glass deep processing equipment, the horizontal glass washing machine focuses on cleaning and drying the glass surface. The equipment adopts a ho...

-

Glass Film Lamination Machine

A glass film laminating machine is a kind of equipment specially used for various types of flat monolithic glass and hollow glass products, which can ...

-

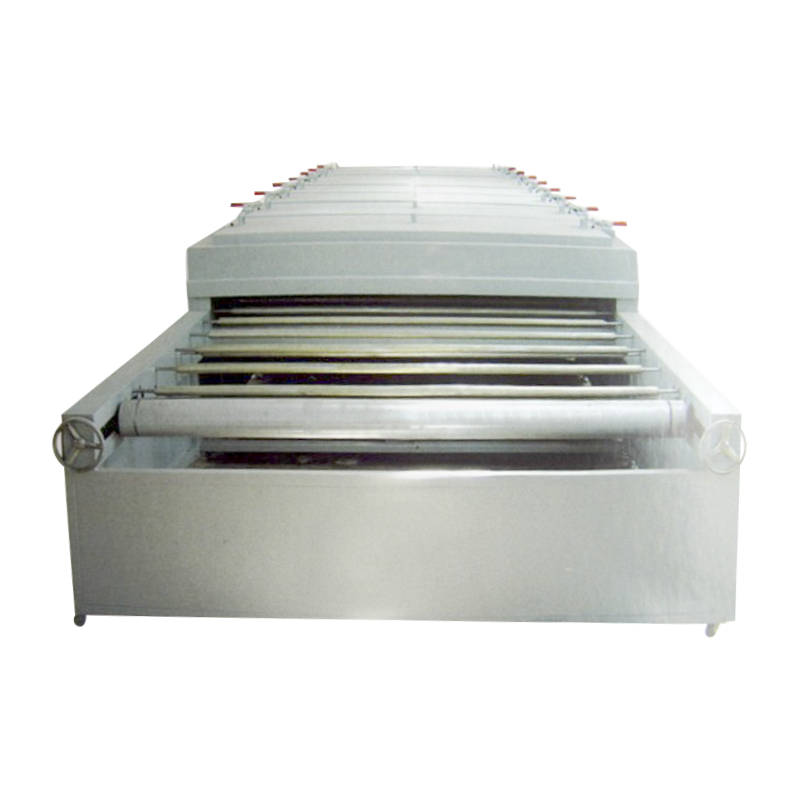

Color Crystal Glass Oven Drying Tunnel

The colored crystal glass oven is specially designed for the drying needs of colored crystal glass. Through a scientific internal structure and a prec...

-

Semi-automatic Flat 3D Glass Screen Printing Machine

The flat semi-automatic 3D glass screen printer is designed for precise screen printing on 3D glass surfaces. The overall structure of the equipment i...

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. is

China Custom Non Woven Fabric Making Machine, Glass Processing Equipment Manufacturers and

Non Woven Fabric Making Machine, Glass Processing Equipment Suppliers.Jingang is a professional enterprise specializing in the research, development, and manufacturing of nonwoven materials and supporting equipment. Located in Jiangyin, Jiangsu Province, China, the company offers a wide range of products including PP spunbond and meltblown nonwovens, which are widely used in industries such as automotive, agriculture, packaging, and deep glass processing.In addition to nonwoven materials, we independently design and manufacture a variety of specialized machinery, including nonwoven production lines, CNC glass edging machines, and printing equipment—dedicated to providing customers with systematic and automated production solutions.

Over the past 26 years, we have remained committed to technological innovation and quality control. In 2002, we successfully developed German-style spunbond technology, improving the stability and efficiency of domestically produced equipment. In 2009, we launched CNC edging machines for shaped glass, expanding the application scope of glass processing. These milestones have played a key role in positioning our company at the forefront of the industry.

We have established a sound quality management system and strictly implement multi-stage inspection processes to ensure our products meet international standards. Through flexible customization, professional technical support, and reliable delivery capabilities, Jiangyin Jingang has built long-term partnerships with clients at home and abroad, earning a solid reputation in the market.We will continue to provide reliable products, strong technical expertise, and practical services to deliver more efficient and sustainable solutions to customers around the world.

-

-

In the evolving landscape of sustainable textiles, Checkered PP Non-Woven Fabric has emerged as a high-performance material that bridges the gap between aesthetic appeal and struct...

READ MORE -

Sesame Pattern PP Non-Woven Fabric, characterized by its distinctive textured surface resembling sesame seeds, is a specialized variant of polypropylene non-woven material. Its uni...

READ MORE -

In the vast landscape of industrial textiles, PP Spunbond Non Woven Fabric stands as a cornerstone material, prized for its versatility, durability, and cost-effectiveness. As a do...

READ MORE -

In the modern manufacturing landscape, precision, efficiency, and versatility are paramount. For industries ranging from automotive to architecture, the ability to cut, shape, and ...

READ MORE

How to Choose the Right Non Woven Fabric Making Machine for Your Production Line

Understanding Your Production Needs

Selecting the right non woven fabric making machine starts with a clear understanding of your production requirements. Key factors include the type of fabric you plan to produce—such as PP spunbond, meltblown, or composite nonwovens—along with target output, material specifications, and application fields. For instance, nonwovens used in automotive interiors or agricultural coverings may require different production line configurations and raw material feeding systems.

Evaluating Machine Configuration and Technology

Modern non woven fabric production lines come in various configurations, such as single-beam, double-beam, and SSS multi-beam systems. Each configuration affects product uniformity, strength, and overall efficiency. It is essential to evaluate machine parameters such as extrusion stability, web forming precision, and temperature control. Advanced technologies like automatic tension regulation and intelligent monitoring systems can significantly enhance production consistency and reduce maintenance downtime.

Quality and Performance Stability

A reliable machine ensures consistent fabric quality and long-term operational stability. Jiangyin Jingang Nonwoven Co., Ltd., founded in 1999, has continuously focused on research, development, and manufacturing excellence in nonwoven materials and supporting machinery. The company successfully developed German-style spunbond technology in 2002, improving the efficiency and stability of domestic equipment. Such innovation reflects the importance of choosing machines with proven design and engineering quality, supported by rigorous testing and inspection systems.

Customization and Technical Support

Each production environment is unique, and machine customization plays a crucial role in meeting specific demands. Choosing a manufacturer capable of flexible customization, from machine width and production speed to automation level, ensures compatibility with your production goals. Reliable technical support, including on-site installation guidance and maintenance training, helps maintain equipment performance over time. Jiangyin Jingang provides integrated technical solutions and automation systems to help clients achieve efficient and scalable production.

Energy Efficiency and Sustainability

As the nonwoven industry moves toward sustainable manufacturing, energy-saving equipment and eco-friendly production processes have become essential. Modern machines are designed to optimize power usage, reduce waste, and minimize emissions, aligning with global environmental standards. Investing in such technology not only reduces operational costs but also enhances corporate social responsibility.

Choosing the right non woven fabric making machine involves more than comparing specifications—it requires evaluating technology, quality assurance, service capability, and long-term reliability. By partnering with an experienced manufacturer like Jiangyin Jingang Nonwoven Co., Ltd., companies can benefit from advanced equipment, strong technical expertise, and dependable service, ensuring stable, efficient, and sustainable production for years to come.

Improving Precision and Efficiency in Glass Processing with Advanced Equipment

Overview of Modern Glass Processing Requirements

In today’s manufacturing environment, industries such as construction, automotive, electronics, and interior design demand high-quality glass products with precise dimensions, smooth edges, and complex shapes. Achieving these standards requires advanced glass processing equipment that combines automation, high precision, and stable performance. Efficient processing also reduces material waste, minimizes labor costs, and shortens production cycles.

Key Technologies Enhancing Precision and Efficiency

Modern glass processing equipment integrates several advanced technologies:

- CNC Control: Computer numerical control ensures accurate cutting, shaping, and edging of glass, even for complex or curved shapes.

- High-Speed Spindles: Spindles with optimized speed and torque improve polishing and cutting efficiency while maintaining edge quality.

- Automatic Loading and Unloading: Reduces manual labor, increases throughput, and minimizes handling damage.

- Real-Time Monitoring: Sensors track temperature, pressure, and spindle performance to ensure consistent product quality.

- Dust and Coolant Management: Efficient suction and cooling systems extend tool life and protect finished glass surfaces.

Example: CNC Glass Edging Machine Parameters

Below is a sample parameter table for a high-performance CNC glass edging machine suitable for both flat and shaped glass:

| Parameter | Specification |

|---|---|

| Glass Thickness Range | 3–25 mm |

| Maximum Glass Width | 2500 mm |

| Maximum Glass Length | 3500 mm |

| Edge Types | Straight, Rounded, Beveled, Shaped |

| Spindle Speed | 0–12000 RPM |

| Processing Speed | 0–20 m/min |

| Automation Level | Fully automated with CNC and servo control |

| Power Supply | 380V, 50Hz, 3-phase |

Continuous Innovation by Jiangyin Jingang Nonwoven Co., Ltd.

Founded in 1999, Jiangyin Jingang Nonwoven Co., Ltd. has steadily expanded its capabilities beyond nonwoven materials to include specialized machinery for glass processing. In 2009, the company introduced CNC edging machines for shaped glass, enabling precise and efficient processing of complex designs. The integration of German-style engineering principles ensures high stability, minimal vibration, and consistent quality.

Automation and Efficiency Benefits

Automated glass processing lines significantly improve productivity:

- Consistent dimensional accuracy across large batches.

- Reduced material waste through optimized cutting and edging programs.

- Lower labor costs due to automated handling and quality checks.

- Faster turnaround times with simultaneous multi-edge processing.

Quality Assurance and Global Standards

Jiangyin Jingang implements strict multi-stage inspection processes and maintains a comprehensive quality management system. Each machine undergoes rigorous testing for accuracy, vibration resistance, and long-term operational stability. Compliance with international standards ensures that equipment can be deployed in diverse production environments around the world.

English

English  русский

русский  Español

Español